NOTE: This file (index.html) is only to preserve old links. New posts after 15-11-2017 will be published here.

Time for Clones

It's been a busy month and the next one will be busy too. I've helped fredrudolf build a v3.3 (aka HP3). We're preparing a live demo at Maker Faire Rome (Dec 1-3). After that, I will help Tom create a video series on Hangprinter. As the bootstrap dev, I'm deeply satisfied with this outlook. So satisfied that my mind is wandering on to the v4 and other RepRap related projects whenever my various inboxes are empty.

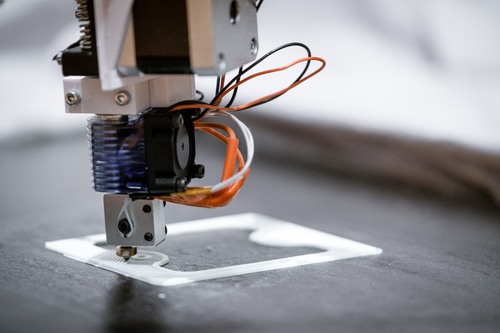

Ok, but first things first. The HP3 works very well:

For now I point all builders to the Hangprinter version 3 forum thread and the BOM and source files.

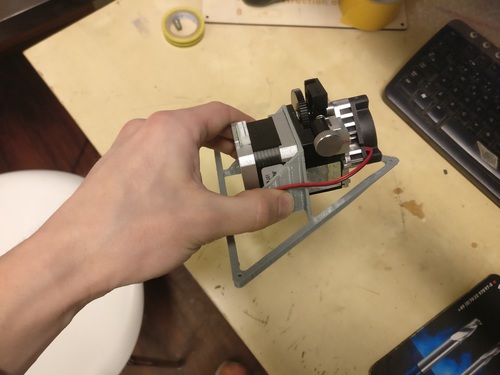

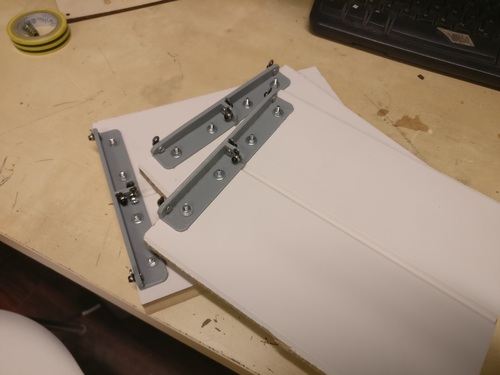

Then second things; my own HP3 winch looks like this:

The winch above is finished hardware-wise. I just need to configure the TMC2130s and mount the thing.

Clone Things and Future Things

"But at all Cost, a Thing RepRap Design must live: with a transfusion of one's own worse Life if one can’t retain the Original's better. Better a live Sparrow than a stuffed Eagle."

- Modified version of Edward FitzGerald's letter to E. B. Cowell, 9/3/1858

I think the HP3 design might just become powerful enough to spread without my long-term help, especially with Tom planning to make instructions for it. I think the makers and the clones will come to Hangprinter and transfuse their own Life into it soon. That will free up a lot of my time, and I'm thinking about what to do with it.

I've tried living the RepRap slogan "Make one for a friend", but my friends fear for their pets' and children's lives whenever I offer them a Hangprinter. I'm considering trying out "Make one for a dev/supporter/potential friend" instead. Since they're so cheap, I can bring physical HP3's out in the world. Drop me an email if you're a dev, supporter or potential friend, and let's see if we can come up with some arrangement.

I'm also considering building an extreme high-performance version of Hangprinter, using BLDC motors and oDrive controller boards. Madcowswe, lead dev behind the powerful oDrive, has shown interest in helping out, and it's very exciting.

A third idea is to capture the pop-culture I've seen grow around RepRap, and give it a proper, distributed social network to grow in. It would emphasize on the social part of 3d-printing and collect everything RepRap in one place. Dev blog, micro blog, campaign, code, chat groups, Youtube stars, and a marketplace. Its goal would be to make peer-production so easy, fun and profitable that people can't resist joining in. Similar web-things are being pioneered in the wonderful Precious Plastics community, see this video.

We're in for an exciting time. Follow me on Twitter for the small updates.

Best regards,

- tobben

Version 3.3 In The Making

It's been a month of very technical development. I feel like I'm searching for the version 3.3 among a forest of new ideas and insights. The goal of closed loop control, automatic calibration and BLDC driven axes are still out in the blue, but pushing towards them has taught me lots of things, and made the v3.3 a much better printer. Anyways.

Going Back to Openscad

I've taken Osika's Fusion 360 CAD files for the version 3 and converted them into Openscad code. This is mainly because Fusion 360 is proprietary software, but also because I enjoy coding full parametrization, and because I have a problem with pain in my mouse arm.

Osika's Fusion 360 models had really nice rounded corners that I loved. This was inconvenient to replicate in Openscad. I've experimented a little with ImplicitCAD. It makes rounded corners in scripted CAD files very easy. The Hangprinter repo will switch to it as soon as ImplicitCAD as gets easy to install.

The Openscad files are in this branch: Openscad_version_3. These files are now the main version that I'm working on.

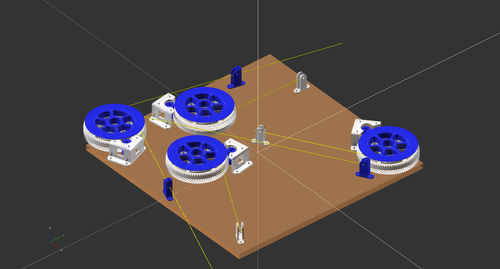

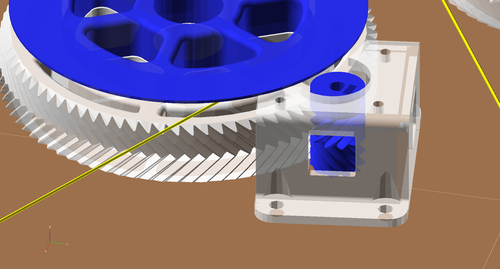

Here's a couple of snapshots from yesterday's Openscad development.

Test Builds

Driving the design work has been little test prints and a goal of making parts less interdependent. I think the v3.3 is already an easier build and a more workable machine than the single unit version 2 was.

I've decided not to include an official Hangprinter extruder in the version 3 repos, at least not for 3 mm or 1.75 mm plastic filaments. Others have made extremely good filament extruders already.

The easily detachable extruder mount takes us nicely towards this month's biggest topic:

Automatic Anchor Localization Work

First off, being able to detach the extruder finally lets us use the mover as an aiming plumb, to get our home position directly below the winch (D-anchor):

The above mentioned tricks helped greatly with the experiments I've been working on this week, trying to locate anchors using only data from force sensing resistors (FSRs). It'd be lovely if it worked, since FSRs are only a few USD each, and they plug right into the thermistor input ports of any 3d printer microcontroller board. They're like thermistors, but sensing compression instead of temperature.

The hope was to maintain a constant, adjustable, and measurable tension on all the lines. This would let us move to known ABCD-positions without knowing the anchors' locations. Data (line lengths) from 9 valid ABCD-positions makes it possible in theory to calculate anchors' (and mover's) XYZ-position through a non-linear optimization routine.

Technical note: If the data points had also included magnitude of each force, we would get better calibration, possibly with fewer data points. See [1] for lots of details. Our data points however, included only line length diffs.

As you see in the video above, the constant tension mode was quite slow. This was due to analog reads on alternating channels is very slow on the Arduino Mega board. A little capacitor has to charge up every time you read from a new analog pin, so there's no way to get completely around this with software. The Arduino Mega, with its 16 MHz and 8-bit processor, is also very slow in itself.

Over a period of three days, I collected a few hundred data points (line length differences compared to those in origo). They were of quite bad quality, +- ca 1 cm. The error grew to +-15 cm in the output of the optimization algorithm.

A few error sources combined up to the +- 1 cm measurement error. First out, it's actually very hard to measure force with FSRs. They drift with both time and temperature, and they have a significant hysteresis. This paper shows a few graphs, explaining a little more. This contributed with at least ca 10% of the error.

The greatest error source however, was inconsistency in spool buildup. I tuned all axes as accurately as I could, but I just couldn't get consistent repeatability. Each spool had ca 10 m of idle line (two 5 m lines) on it, which I think a Hangprinter should be able to handle. (Who would want to run out of line on their 45'th day on a 5m tall print?) Winding and unwinding even a single axis' two lines often ended up making one of the lines ~2 mm shorter than the other. This is the same effect as caused the tilt problem during the Babel tower print in February this year.

In version 3.2, we had reduced spool radius and did a few quick experiments to confirm that line buildup compensation could handle it. It turns out now that we were wrong and must increase spool radius if we want to avoid having to deal with encoders.

Other error sources:

- Flex introduced by sensing element (probably ~1 mm).

- We don't know if we managed to start measurements exactly at home position. A quick repeatability test suggested a +-1.5 mm difference from data collection to data collection.

- Parallelograms between anchor points and action points not exactly parallel.

To sum up the FSR work: I couldn't collect accurate data because axes didn't move accurately. FSRs were convenient and easy to set up but slow and complicated to use. If you want a good printer, use Mechaduinos instead. It's 10 times as expensive, and 10 times as hard to set up, but more than 100 times better.

If you are from the future, and have got a faster processor and bigger spools, and you want to re-check if FSRs could be way to go for auto-calibration, then I salute you. You are probably right! Have my files: firmware and gcodes, and optimization algorithm with data.

Chris's Basement

To end on a high note, I must point out Chris Riley (aka brotherchris)'s Hangprinter videos:

- Hang Printer - 3D printer Build Part 1

- Add Bluetooth to your 3D printer

- Hang Printer - 3D Printer Build UPDATE

- Hang Printer - 3D Printer Build Part 2 Calibrate & First Print

- Hang Printer 300mm Benchy print - Time Lapse

If you're building a version 2 yourself, I highly recommend you to follow his ongoing dev work on the forum thread. You rock, Chris!

- tobben

Benchy, Videos and Some New Code

First Hangprinted Benchy:

We're planning to try changing the Mechaduinos for FSR-driven tightness sensors. Code for this is written and posted on v3_fsr branch in the repo.

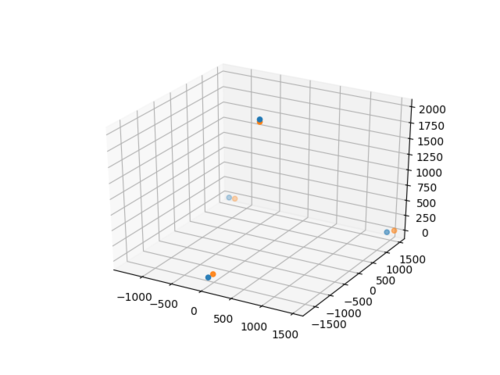

We did a few more tries at collecting data for auto locating anchor points. One of them looked like this:

After that try we updated the macro to use constant torque mode on all motors before doing the actual measurement, with only marginally better results. Updated gcode macro is here. We also noticed we needed to send data through stderr for Pronterface to show them during "print"/macro execution. All the code we run on the v3.2 is published on the Gbg_version_3 branch in the repo.

The last thing that happened this month was a Hangprinter demonstration at The Conference in Malmö.

Thanks to Jaime Reyes who helped me out for two intensive days in Malmö!

- tobben

Version 3.2 Overview

The Hangprinter v3 has developed very quickly recently. We've been developing so intensely, we almost forgot to print a Benchy with the current prototype, called v3.2. Being a first print, it of course failed with a thermal runaway error, but accuracy and precision looks promising:

The v3.2, like the other v3 prototypes, is a dual unit design. It has a stationary part, called the Winch, where the microcontroller, the motors and all the spools are mounted, and it has a moving part, called the Mover, where the tool head (currently extruder and hot end), is mounted. Its source files are found in the Gbg_version_3 branch in the repo. All CAD files created by Osika.

The v3.2 Winch

The new winch has a few features worth mentioning:

- Structural integrity is provided by a slab of MDF.

- In addition to being a winch, it also serves as a D-anchor. Hence the hooks in the corners.

- Spool size is decreased and line diameter has increased. Spool buildup compensation has been found to work well (less than 2 mm errors along 1 m moves), enabling us to boost ease of use and ease of assembly in this way.

- Rolling fairleads with U-bearings and PTFE guiding have been added for the A, B, and C axes, both on the winch and at the anchors. We found that hysteresis was introduced by friction between the new, thicker 0.5 mm Fireline and the lamp hooks. The D-anchors will also be replaced with rolling fairleads, files are already in the repo.

- Few dependencies among different parts. We didn't even plan the motors- and spool placements in detail, we (Osika) just assembled it.

The Mover

The v3.2 mover also feels simple, it's hard to find very much to explain about it.

It has a few features worth mentioning though.

- It's very light, allowing quick acceleration and decelerations.

- All action points are at the same height, making z-calibration (relative localization of anchor points along z-axis) easier.

- Action points are 42 cm apart, longer than on any other mover we've made, giving it a large print volume.

- Both A-lines are attached to the same screw, that can slide back and forth along the side of the triangle. This allows mover z-rotation angle to be adjusted very easily.

- It has space for potentially much larger tool heads than the one currently used.

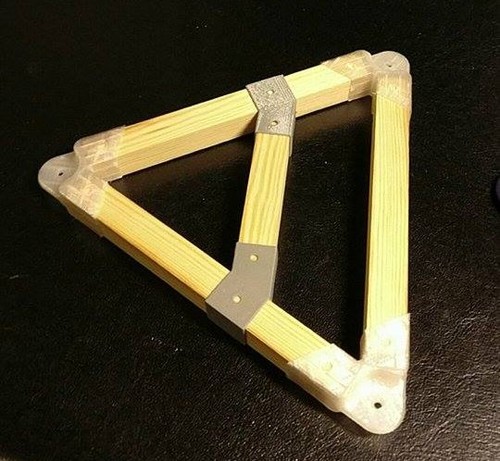

- Corners fit movers of any beam length and material, see pic from previous post.

Constant Force Mode

In the video above, Osika is pushing the mover around by hand, without issuing commands or thinking about gcode. This mode of operation on the v3.2 is enabled by the Mechaduinos running in "torque mode", sending constant amounts of current through each stepper motor. It allows us to quickly place the mover at working height or in origo, and it generally just feels nice to control the machine with our muscles. This mode is the successor of Vilse's "button mode" presented in an earlier post.

Automatic Localization of Anchor Points

The constant force mode, along with the Mechaduinos' encoders and a few new gcodes has finally enabled us to do some real testing of the auto calibration algorithm presented earlier. The new gcodes are G95, G96 and G97.

- G95 A[torque] B[torque] C[torque] D[torque] - sets motor(s) in torque mode, applying specified torque between -255 and +255. Negative torque winds line, positive torque unwinds line. Zero torque fixates axis and sets it back into position mode.

- G96 A B C D - Sets the reference point for specified motor's encoder.

- G97 A B C D - Read specified motor's relative encoder value and calculate how many millimeters of line that has been wound/unwound since the previous G96-command was issued for that axis. Only accounts correctly for line buildup if G96 was issued in origo with lines tight.

The Ugly Part

All of the above commands require the Mechaduinos to communicate with Hangprinter-Marlin, which in itself is a bit of an ugly duckling of the project. It may be the oldest fork of rotten spaghetti Github ever hosted. Not Italian and with no tomato sauce. But it works.

Anyways, to enable required communication, I've hooked all Mechadionos onto the RAMPS' i2c bus.

The ongoing discussions about how to replace the RAMPS+Mechaduino-solution is very pleasant since anything is better than the above. But all those ugly parts enables testing of automatic anchor localization =D Hoooray!

Some basic usage of G96, and G97 is shown in the following video. Also note the already scrapped v3.1 winch and forest of green/yellow dupont cables connecting i2c bus near end of video.

The Theoretical Part

Slightly more advanced usage of G95, G96, and G97 are detailed in the following auto-calibration gcode macro: link.

That macro also makes heavy usage of the new G8 gcode, which lets you control line lengths like Cartesian RepRaps control XYZ-positions with G1, while compensating spool buildup.

For example G8 A10 F100, would make line A 10 mm longer than it is in origo, moving at a speed of 100 mm/min.

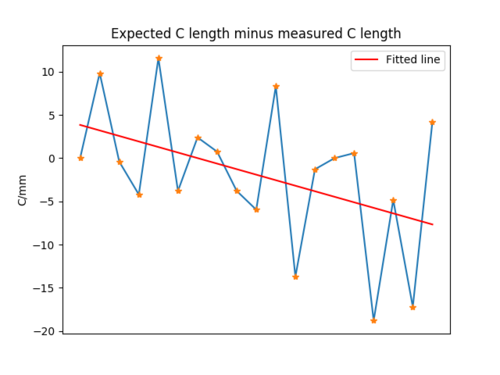

The basic idea of the linked gcode is to use the C-motor as a sensor. It moves the A, B, and D motors by known amounts while the C-motor unwinds line. Once A, B, and D arrives at the known positions, motor C will tighten its line with 20% of its max force, read its encoder, and release its line again. This repeats 27 times in the macro. The linked gcode didn't work perfectly, but I managed to collect 18 consecutive data points, which is enough to auto-calibrate, at least in theory.

In practice, the algorithm wanted far more and/or far better data. With my 18 data points it was only able to locate the anchors within +- 37 cm along each axis. The reason for this is of course imprecise measurements. The Mechaduinos' torque mode doesn't actually provide a constant tension in the C line, since gear teeth don't transfer torque perfectly smoothly. We'll be testing if a force sensing resistor along the sensor axis' line can give us better data. Until then, very wide herringbone gears will also give us better data.

The error's mean value was -1.9. A positive value was expected since the C-motor will wind up extra line for all flex that exists in the system. We could clearly have tightened the line harder, particularly during the last 8 measurements when the C-line was shorter. This makes sense, since the A- and B-lines worked at a better angle, and probably flexed less towards the C-anchor when the C-line was shorter.

The error's standard deviation was 7.95. This is high. The auto-calibration algorithm needs a standard deviation below ca 2 to produce better calibration values than I can measure by hand.

Expected values were known because we measured the anchor positions by hand. Those measurements induce systematic errors that would largely be compensated by subtracting the red line from the data. However, the algorithm's output did in fact get slightly worse after subtracting the linear error.

A more complete and accurate description of the auto-calibration results are hidden in the script i used, as well as in other files in the data3 branch in the auto-calibration repo.

On the positive side, it was discovered that the auto-calibration algorithm improved its convergence rate drastically when we forced the first measurement to be in origo. I'm quite pleased to have a concrete sense of how much I need to improve measurements before I can actually auto-calibrate.

- tobben

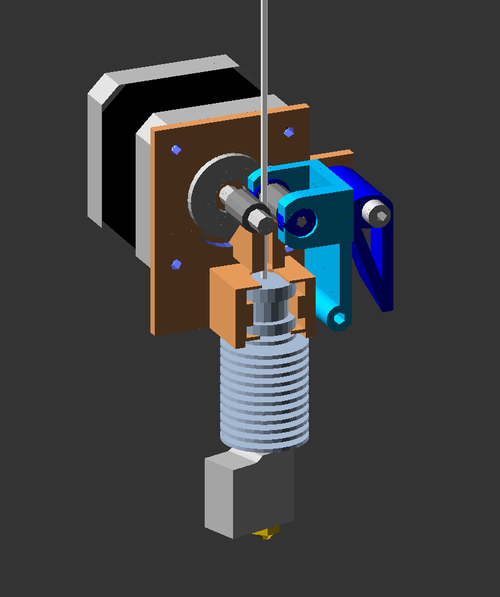

Closed Loop Doing its Job and Sstruder v2 Pic

The Sstruder v2 files are published in the repo without any assembly instructions. Here is how I currently use it:

Notice the bowden tube guiding the filament both above and below the hobb. Also note that the idler (middle 623 bearing) is placed along the filament path, and secured in place with M3 nuts. The idler shaft is an M3 screw with objects stacked/screwed in the following order: Screw head -> 623 bearing -> nyloc nut -> nut -> nut -> 623 bearing -> nut -> 623 bearing.

- tobben

Working on Auto Calibration and Reliability

I put together a closed loop single unit Hangprinter with pancake steppers recently. The following video shows that it can run upwards along the D-line at 26.6 mm/s. It is driven by a 17HS08-1004S, rated for 1A but running at 0.56A. Axis speed is limited by motor stalling/driver resonance.

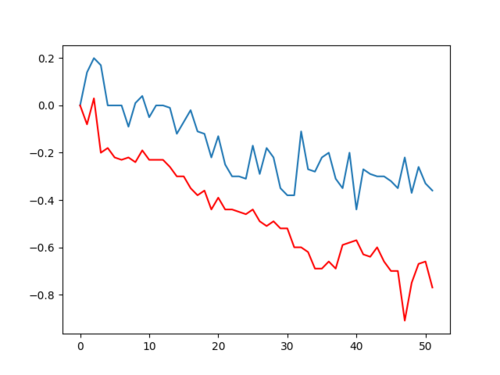

This single unit machine will help me learn to collect data for the auto-calibration procedure. Collecting data from single units will be hard because of their large mass. The auto-calibration algorithm requires less than 2 mm errors in relative line lengths compared to what a massless point would observe. With a random error of 1 mm convergence now looks like this:

I'm considering the auto-calibration coding as done for now. In the end it was the excellent paper "Calibration of a fully-constrained parallel cable-driven robot" that made me understand that Newton's method was way to go, and that the analytical Jacobian wasn't worthwhile putting into code.

I'm rounding this post off with thoughts around a funny pic:

Mechaduinos kind of go against design principles of the Hangprinter Project. They cost $50/piece + shipping, they have wasteful amounts of 32-bit processor cycles, they're hard to self-replicate, they're quite complex to just mount, program and calibrate and easily double the assembly time of an average Hangprinter. On the other hand, they're OSHW and they can make the Hangprinter work without a babysitter, now.

The Babel Tower print made me concerned about Hangprinter reliability, so the Mechaduinos are there to teach me about closed loop control. In the future load angle data from back emf might provide the reliability we need. Thanks to Elijah Craig for showing me the TMC2130 drivers! They can output such data =)

- tobben

Walking the Line

Following up on what I planned 35 days ago:

"When the version 3 is up and running, I will focus my dev time on adding closed loop control, auto calibration and DC motors, in that order. Well, at least that's the plan right now. I'll prioritize improvements that apply to both single- and dual unit Hangprinters, and keep both branches alive."

Getting Version 3 Up And Running

The version 3 referred to a dual unit design with large spools like shown in the previous post. This was supposed to reduce weight and reduce spool buildup. The version 3 since got thinner FireLines (0.18 mm, down from 0.39 mm in version 2), which further decreased buildup by a factor of 4.5:

The version 3 is up and hanging, but is not yet up and running.

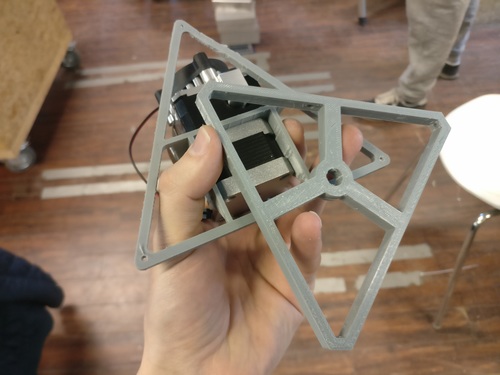

Small Side Note on Movers

The mover depicted above (moving unit with extruder) is a triangle of Open Beams with a E3D Aero mounted at its center. It's a scaled up design revision of Osika's small Aero Titan mover. He has started constructing movers in the following material agnostic manner:

Adding Closed Loop Control

The Mechaduino Project has given us a plug-and-play loop closer.

This means that Hangprinter version 3 users can count on prints actually finishing. A great relief. The plug-and-play Mechaduino setup, as well as the possibility to construct custom stepper-servos based on the Mechaduino Project has made us really excited. We've added Mechaduinos to version 3's A, B, and C axes at a total cost $150.

Adding Auto-Calibration

Vilse has done some impressive work on simulation and data collection. Matlab simulation is available here. To auto-calibrate without user interaction, we need to

- Sample relative line lengths \(\theta\) with tight lines at unknown positions \(x_i\) starting from an unknown start position \(x_0\).

- Solve a large non-linear system of equations numerically to find the best fitting set of anchors positions \(a\) and positions \(x_i\).

Luckily, very skilled researchers have solved this problem before us and published their results. Studying this paper has helped my own understanding a lot.

To be able to quickly make sample \(\theta\), Vilse created "button mode". Obviously. It is useful whenever you want to push your Hangprinter around, which is quite often:

The button mode related modifications to the Hangprinter-Marlin firmware are available here.

We haven't tried seriously to add DC motors yet, but we stay by the plan to do so further down the road.

- tobben

Experimental Dual Unit Designs

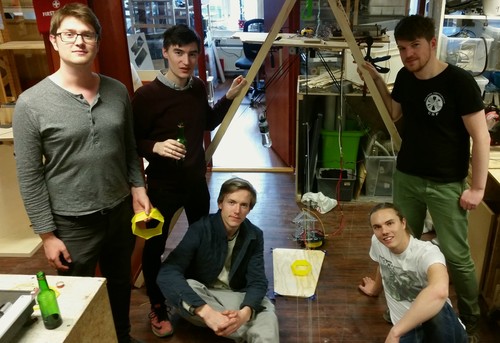

The Hangprinter Hackathon at Bitraf produced some technical progress.

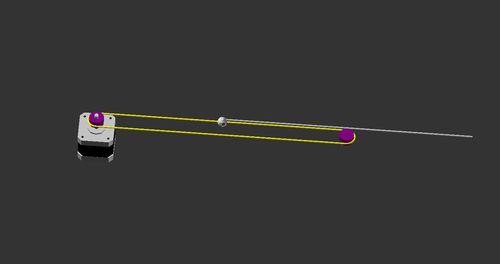

Besides dividing the Hangprinter into two units, the GT design also tried out the concept of spanning up linear actuators between winch and ABC anchor points:

This concept works wonderfully in theory, and you can even use belt for the yellow loop to make it easy to build. In practice you need to keep the loops very tight, or the belts will skip. We did a quick and dirty patch to solve this. The dangling bottle of water in the picture above is what keeps our D-line tight.

The Hangprinter GT turned into a quite bulky installation, so the design won't be continued. It did shed some light on a few pros and cons with dual unit Hangprinters in general.

- Pro: Easy to snap together. Few parts that need to fit each other.

- Pro: No absolute requirement of wireless communication.

- Pro: Lighter moving unit allows quicker accelerations.

- Pro: Increased modularity. ABCD actuators, electronics department and moving unit can be swapped out independently.

- Con: Stepper- and hot end cables must be extended manually.

- Con: Max stepper cable length (a few meters) limits mounting options.

Back to Spool

The Benefit of Large Spools

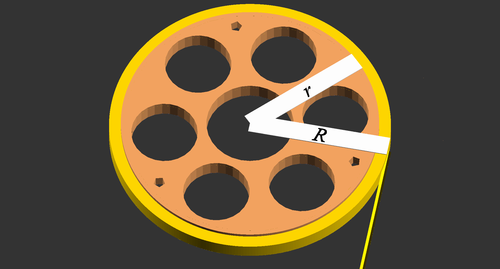

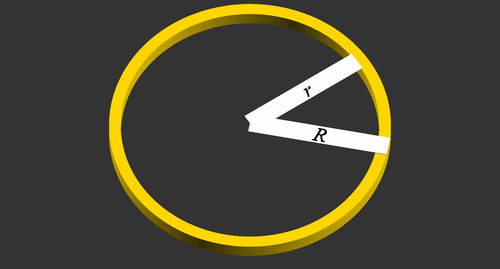

The spool radii are doubled as compared to the standard Hangprinter spools, in order to decrease line buildup. A doubled spool radius reduces spool buildup to ca 1/4. Let's step through the maths to kill some time:

To wind in \(2r\) of line onto an empty spool with radius \(r\), we would need to rotate the spool by 2 radians. A spool with \(x\) meters of line already wound onto it would have \(\epsilon(x)\) of buildup added onto its radius \(r\). It would wind in \(2(r + \epsilon(x))\) of line if it were rotated by 2 radians. Without buildup compensation the resulting error would be

\begin{equation} \text{err}_r = 2\epsilon(x). \end{equation}To wind in \(2r\) of line on an empty spool with radius \(R=2r\), we would need to rotate the spool by 1 radian. A buildup of \(\delta(x)\) would cause an error of

\begin{equation} \text{err}_R = \delta(x). \end{equation}The circumference of the spool with radius \(R=2r\) is twice as long as the circumference of the spool with radius \(r\). The buildup caused by \(x\) m of line should therefore be ca halved on the big spool, which gives us the approximate total benefit of doubling spool radius:

\begin{equation} \text{err}_R = \delta(x) \approx \epsilon(x)/2 = \text{err}_r/4. \end{equation}But wait, there's more. The spools depicted above are also 2 times higher than standard Hangprinter spools. This should cut buildup in half once again.

If that isn't enough then there's also the possibility to tie in lines mid-air, and run a single line around each spool. This wall of text has already gotten the line buildup down to 1/8 of what we had before anyways, so let's wait and see if this is really necessary.

The buildup problems of Hangprinter version 2 were mostly on the D-axis, which had doubled lines (mechanical advantage 2). We can drop that on version 3 since it has a light moving unit. To summarize, we cut D-axis buildup to 1/16 and leave ABC buildup at 1/8.

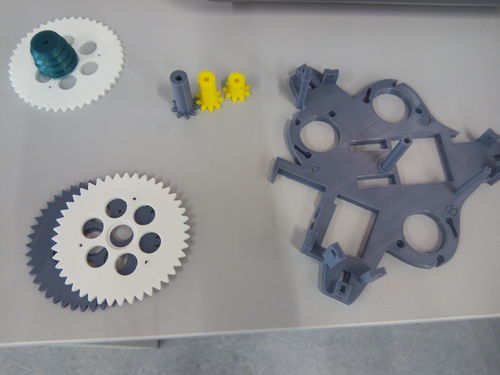

After all this theory let's rest our eyes on some Hangprinter version 2 parts designed and printed by Alexander Osika:

When the version 3 is up and running, I will focus my dev time on adding closed loop control, auto calibration and DC motors, in that order. Well, at least that's the plan right now. I'll prioritize improvements that apply to both single- and dual unit Hangprinters, and keep both branches alive.

- tobben

Other People's Hangprinter Builds

- tobben

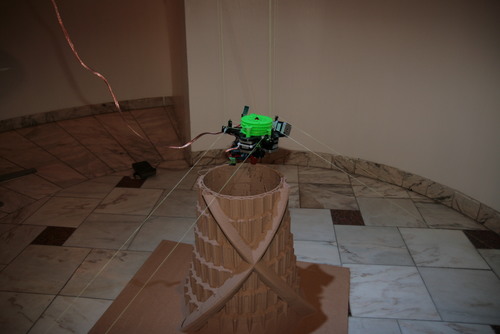

Babel Tower Time Lapse

To recharge before the Hangprinter Hackathon in Oslo next weekend, I threw together a Babel Tower time lapse.

Enjoy!

- tobben

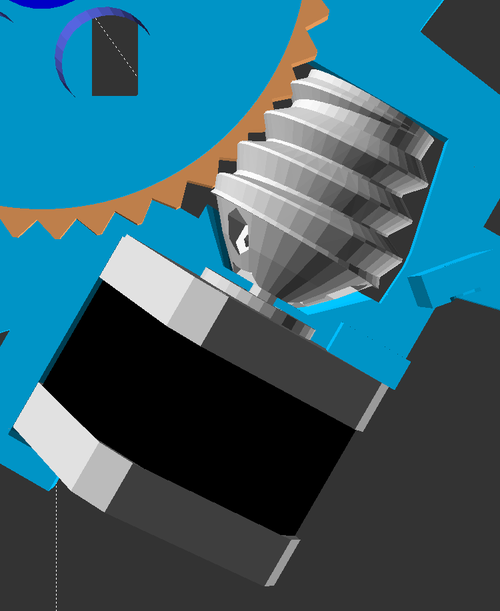

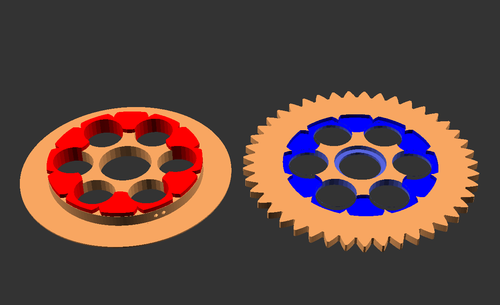

First Pull Request Merged

The Hangprinter repo on has had its first merged pull request! Committer was awigen. See commmit here. The code is about adding an axle to the worm. I've been wanting one for a long time, so I was very happy about the pull request. After some further refinements, the worm now looks like this:

Finally I'm not alone in the repo anymore =)

- tobben

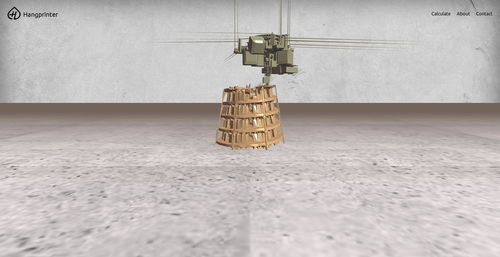

Hangprinter.org

Check it out: hangprinter.org! Big thanks to Piyush Dharnidharka for taking the initiative and building the page.

It has a practical Hangprinter Calibration Calculator page that implements the equations from the calibration manual.

There's also an about page featuring some links and a text.

- tobben

Push Fit Sandwich

In this forum post, NOVAprint confirmed what I had suspected was a weakness in the sandwich design. A gap might open between the snelle and the sandwich gear, so that line wraps around the center cylinder. I never really liked the super-short screws in the sandwich either, so I've designed a push fit solution:

The master branch of the repo has been updated both with scad-file and new stl files. Be warned that I haven't tested these files. If you want the old files, they're back in the version 2 branch of the repo.

I've been alone in the repo for so long, it has turned me into that guy.

- tobben

Sstruder v2 and Helsingborg

I got the chance to test the improved extruder design recently. It worked better than the previous Sstruder, so stls were pushed to the repo today.

I also tidied up the stl directory in the repo and experimented with high travel moves. The Hangprinter moved at 360 mm/s without loosing steps or accumulating errors. It didn't move in straight lines, but it reached its planned end point.

I spent the weekend Hangprinting at 3D Meetup in Helsingborg. Thanks to the organizers, you did an amazing job! Based on the feedback from Helsingborg, I think the whole Hangprinter community thing is starting to get legs: [twitter.com], [twitter.com]

- tobben

Tweets

I posted a few Tweets recently. Reposting them here now.

- tobben

The Tilt Problem

Hello Reprappers and Hangprinterers! The Babel print gives a lot of lessons, so there's a lot of posts this week. Ca 1.5 m above ground and with 20 m of line on the D-spool, I've noticed a previously undocumented problem.

The D-line from the corner where the B- and C-sides meet consistently sees a larger spool diameter than the other two corners. I suspect that subtle differences between the D-fish rings may cause this effect, or that it is simply the weight of the D-motor causing this. It is interesting that one corner travels faster while the other two corners stay perfectly horizontal relative to each other.

Anyways, structured debugging is a job for future tobben. Present tobben just wants to show you another full figure picture of the print:

My next post will probably drop the SI unit system.

Instead it will leverage on big data and impact the value added Internet things, featuring intelligent solutions for new normals as required by next generation info capitalism in the cloud (with diamonds).

Disruption will make language hyperlocal like a mashup of microservices in a web of buzz. Later it will drop-swap written words for virtual broadcasted brandcasting on a blockchain. (It's just a bit more deep and viral, you know.)

Diversity and non-scalable divergence will immerse the paradigm through the re-realization of a withholding economy, and possible grand scale peer-to-peer destruction facilitated by social analytics and the evolution of physical cookies pushing us towards mobile nanomodularity and some seriously driven development.

;)

- tobben

Changed Anchor Points Mid Print

I managed to sneak up the anchor points yesterday. The secret trick is to pause and move one anchor point at a time. Then run a few rounds very slowly after each change, adjusting calibration errors manually with small G6-moves.

I my case, each anchor movement still produces visible artifacts on the print:

If you plan on making anchor point movements mid print, I recommend moving them only along the Z-axis and making the movements in increments of ca half the distance between anchor point and origo.

Ok, enough about the errors, time for a full figure picture:

The project of Hangprinting a Babel Tower happens in Sliperiet, Umeå, Sweden. It is part of the +Project (Swedish link here). More about Sliperiet is found here.

- tobben

Slowly but Surely

The tower is modelled with OpenSCAD. Repo here.

I'm trying to move the anchor points upwards mid print, but I haven't really nailed the re-calibration yet...

- tobben

Community at Embryo Stage

It seems like some collaboration and maybe even a little community is gathering around the Hangprinter Project. Right now, there are 5-6 builders out there wrapping their heads around the source files, assembly process and calibration.

No one has sent any pictures though, and I'm a bit worried that builders will lose motivation when they bump into challenges (bugs that I wrote).

Hang in there! The ceiling is the limit!

- tobben

D-Wobble Debugged

Those who have zoomed in on my Hangprints after I added the worm drive will have noticed a periodic error. The following pictured Hangprint shows the problem quite clearly:

This error arose because my Hangprinter's worm has not been mounted straight along the motor shaft.

The above animated wobble is a bit exaggerated. You can see and hear the actual wobble in the following old video:

The root of all this wobbliness is a non-straight flat part on the shaft itself.

The motor is covered in tape because I'm about to start grinding the flat area into straightness. Debugging is so delightful when the cause gets obvious within 10 minutes and the solution involves grinding!

Until next time.

- tobben

Experimental Line Buildup Compensation Feature

I've conducted a few experiments recently, and I think I've arrived at a usable implementation of the line buildup compensation that I described in an earlier blog post. In this post, I'll try to go a bit more in detail.

The Problem: Account for Changing Spool Radius

Most RepRaps have simple linear relationships between motor position and hot end position. If their hot end is at the position 100 mm along an axis, their corresponding motor is at step number

\begin{equation} m = 100\cdot \text{s}, \tag{1} \label{1} \end{equation}where \(\text{s}\) is a constant and \(m\) is the motor's step count.

Hangprinter can not use this simple linear relationship because it winds line around spools. When there is more line on the spool, the motor winds up more line per step because of the increased radius resulting from line buildup.

We need to change the linear relationship \(m = x\cdot\text{s}\) with a more complicated relationship \(m = f(x)\).

Step 1: Find Conversion Factor for Infinitesimal Movement: \(\text{s}'\)

Say we want to move an axis from \(x_0\) to \(x_0 + \text{d}x\). A simple linear relationship, like in Equation \eqref{1}, will be valid if \(\text{d}x\) is small enough. We still have to find the correct conversion factor \(\text{s}'\), but this is easy as long as we can assume \(R\) to be constant.

Let \(\alpha\) be the number of radians that the spool rotates when the motor makes 1 full revolution. On Hangprinter version 2 the motors's gears have 9 teeth and the spool's gears have 43 teeth, so we get \(\alpha = 1.32\). Looking at Figure 1, and assuming \(R\) constant, we would move \(R\alpha\) by doing 1 full motor revolution. Now say that the motor makes \(t\) steps per revolution, and we have our steps per mm:

\begin{equation} s' = \frac{t}{R\alpha}. \tag{2} \label{2} \end{equation}Step 2: Make Radius Depend on Position: \(R(x)\)

In Figure 1 we approximate the buildup as a rectangular torus shape, and \(R\) depends on the volume of that torus.

The volume of the torus depends on the amount of line on the spool like so

\begin{equation} \text{Volume} = h\pi(R^2 - r^2) = vx, \tag{3} \label{3} \end{equation}where \(h\) is the height of the spool, \(v\) is the volume per unit line, and \(x\) is the position along the line that corresponds to \(R\). Note that we need to give \(v\) a negative sign if we define the positive \(x\)-direction to be the direction we move when we unwind line. Rearranging Equation \eqref{3} gives us

\begin{equation} R(x) = \sqrt{\frac{vx}{h\pi} + r^2}, \tag{4} \label{4} \end{equation}Step 3: Make Conversion Factor Depend on Position: \(s'(x)\)

Combining Equation \eqref{4} back into Equation \eqref{2}, we get

\begin{equation} s'(x) = \frac{t}{\alpha\sqrt{\frac{vx}{h\pi} + r^2}}, \tag{5} \label{5} \end{equation}Just for reference: apart from missing a factor to account for mechanical advantage, the above equation corresponds exactly to the equation I presented in a previous blog post, see Equation *. In that equation, \(x\) is split up into the parts to account for mechanical advantage and calibration procedures. In this theoretical review, we rather want to simplify our notation, like this:

\begin{equation} s'(x) = \frac{a}{\sqrt{c_0 + c_1x}}, \tag{6} \label{6} \end{equation}where \(a = \tfrac{t}{\alpha}\), \(c_1\) is the factor that multiplies with \(D\) in Equation * and \(c_0\) is the rest of the constants below the root sign in Equation *.

Step 4: Testing...

I mentioned in the beginning of this post that I've conducted some experiments. I found that continuously re-applying Equation \eqref{6}, and using the computed values like \(m = x s'\) doesn't produce nice results.

Similarly miserable results were achieved by applying Equation \eqref{6} at a constant frequency:

Step 5: Make \(\text{d}x\) Small Enough Using Theory

A problem with the above approaches was error accumulation. Say the Hangprinter reached point \(x\) with \(m_0\) on its step counter. A few minutes later, Hangprinter reaches \(x\) again, but truncation errors have put the step counter to \(m_0 + 1\). Steps per mm is calculated solely based on \(x\), so it is totally random whether the next truncation error gets us back to the correct \(m\), or if the error will be increased to \(m + 2\). This randomness gives the typical random walk pattern along the vertical edges in Figures 3 and 4.

To get back on track with finding \(m\) in Equation \eqref{1}, we integrate \(s'(x)\) from zero to \(x\). This integral gives us a one-to-one mapping from \(x\) to \(m\).

\begin{equation} m(x) = \int_0^{x}{s'(x')\text{d}x'} = \frac{2a}{c_1}\big(\sqrt{c_0 + c_1x} - \sqrt{c_0}\big). \tag{7} \label{7} \end{equation}I was quite surprised that all this theory and volume calculations got me from a straight line relationship to an almost equally simple square root relationship. I feared that line buildup compensation would be computationally intensive, so I'm quite pleased it's only one addition, one subtraction, one multiplication and one square root extra, compared to no compensation. Even an my old Atmega2560 can handle that. In the actual firmware, I've changed notation again, so it looks like this:

target[A_AXIS] = lround(k0a*(sqrt(k1a + k2a*delta[A_AXIS]) - sqrtk1a));

And finally the first test print to prove it all kind of works:

It's nice to see the printer moving more than 1 m upwards without over-tightening any lines, and then back again to the same millimeter! It almost looks functional.

- tobben

Hangprinter Presentation Video and Campaign

I've been helped by some friends to make a campaign. It has a presentation video and a logo and a picture of me and everything! Get to it by clicking the logo below. Please share, comment and make the Hanprinter Project your own.

The goal of the campaign is to allow Hangprinter to grow faster and more user friendly. Hangprinter needs a dev team. It's made to be useful, so it also needs to spread. To spread more, it needs more of this:

- tobben

Compensation May Allow Bigger Prints

The line compensation code may increase print volume noticeably. During testing, it has allowed Hangprinter version 2 to go places where version 1 surely would have over-tightened lines and skipped steps. Read more...

Compensating Line Buildup on Spools

I've added to Hangprinter-Marlins some code that compensates for line buildup on the spools. Without it, I found that error in steps/mm grew to several percent as print dimensions grew close to 1 m. The problem was particularly noticeable on the D-axis since it has three doubled lines, so moving 1 mm in the D-direction puts 6 mm of line on the D-spool. Read more...

The Worm Drive Works

Just tested the worm drive. I was so happy to see it work that I made a little video. Read more...

Adjustable D Line Lengths and New Look

Just made the D-line lengths easier to adjust independently. This is useful to get Hangprinter's corners in level with bed. Newest changes are at a new branch in the repo. Read more...

Worm Drive on D-axis

The best part is that the worm is pure parametrized OpenSCAD and renders nicely. Read more...

Another Stop Motion Video

Hangprinting 0.9 m high twisted P at Teknisk Museum's 3D-printerfestival. Note: this text was edited on 7-11-2016. Read more...

Hangprinter Calibration Manual v0.1

This post will make it easier to calibrate Clerck by avoiding the need for measurements like this: Read more...

Oslo Skaperfestival 2016

Clerck was demonstrated in public for the first time this weekend! Read more...

Homing the Hangprinter Without Adding Hardware

I've thought some more about Hangprinter recently, since I'm going to demonstrate it on the 3d printer festival arranged by the Norwegian Museum of Science and Technology in Oslo. I've only ever mounted and calibrated Hangprinter once before, so getting the manual homing to work fast enough worries me a bit. I don't have the time to implement the proposed accelerometer dependent homing procedure before the festival. Read more...

Yet Another Very Simple Extruder Design

I've thought about a second generation Hangprinter lately, including the extruder. My current favourite re-design uses two motors running synchronously. Read more...

Why Optimize Chaotic Production?

RepRappers have noticed me that basing the story line of my my Master's thesis on productivity numbers doesn't resonate with them. This tickled me to think about and formulate why I do what I do, hence this post. Read more...

Portable Gcode and Short Status

Today I asked a question on reprap forums that has puzzled me for a long time. Why don't we share gcode instead of 3d models? The technical obstacles are small and it would be an obvious optimization of chaotic production. See the forum post for details. Hoping for an interesting discussion there. Read more...

Optimize Chaotic Production

I presented my Master's recently, with a story line that was very RepRap centric. I'd like to re-present and develop my thoughts with some colors here. Be warned that this is a post about why I RepRap, not how I RepRap. Read more...

Update and Clerck Build Instructions

I've been working on Open Source Ecology 3D printer workshops (see my work log for exactly what I've been up to) the past month, and will continue to work on that until mid summer. Read more...

Links

Hangprinter Campaign: Bountysource Salt

Hangprinter Project: [1], [2], [3], [4], [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [21], [22], [23], [24], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34], [35], [36], [37], [38], [39], [40], [41], [42], [43], [44], [45], [46], [47], [48], [49]

Print Issue Solution Filter Project: [1], [2], [3], [4]

Sourcing RepRappro Mendel in Larvik: [1], [2], [3], [4], [5], [6], [7]

Archive: 2014, 2015, 2016, , 2017

Github Profile: link

Vimeo User: link

Twitter User: link

Work Microblog: link

Master's Thesis: link

Linkedin Profile: link

Appropedia User: link

Company website (in Norwegian): link

Email: post@ludvigsen3dprinting.com

RepRap Forums User: link

Forums threads: Hangprinter version 1, Hangprinter version 2, Hangprinter version 3

Source for this blog: Github repo

Everything on this homepage, except the videos, is licenced under the Gnu Free Documentation Licence. The videos are licenced via Vimeo or Youtube.