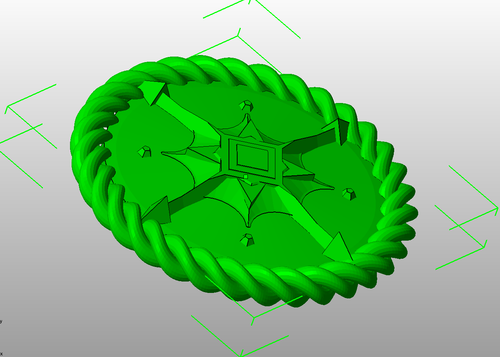

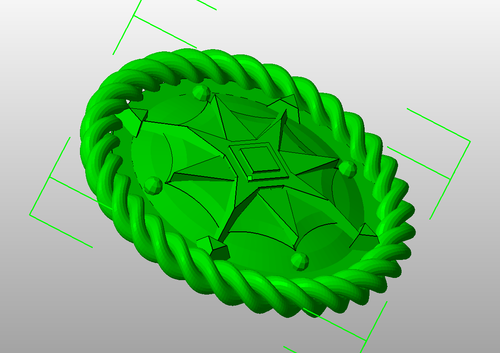

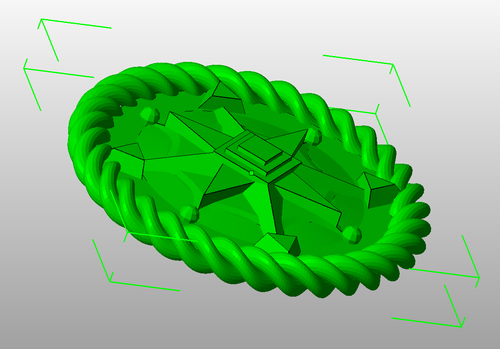

Printing small details

I was contacted by a silversmith recently, that was in the process of making a batch of buttons for some seafarers. He gave me this sketch, that the sefarers had given him:

In addition, I got instructions to put a rope ring around the button to protect from the pointy arrows.

The special challenge for me in this was the scale. The button was to be produced with two different diameters: 15 and 20 mm. Height: 1 to 3 mm. In other words, the details need to be less than 0.33 mm high, and sometimes ca 0.3 mm wide.

First thing I did was to order a 0.3 mm nozzle from Emakershop. Second was to make a Git repo which can be found here. Wish I had more time to describe the process, but a picture of todays prints have to do for now.

- tobben

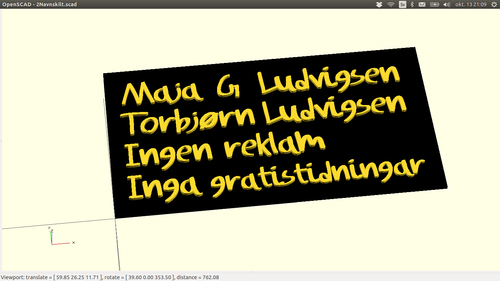

A Cumbersome Beautiful Way of Creating Signs in OpenScad

I needed a new sign on our mailbox outside our house recently, so I thought I might as well make a two colored plastic sign this time, since the paper ones only seems to last for one year or so. If the plastic sign can be used for more than 10 years, this project might even be a net time saver.

I have made models with letters in them several times, and every time I have ended up doing it differently. This time, I found a little Python script, called font2openscad, that converted True Type Fonts into OpenScad-importable dxf-files. I wanted to use the letters one at a time, so I wrote a little module:

module letter(path, trx=0, height = 3){

translate([trx,0,0])

linear_extrude(height=height, convexity=10, slices=2) import(path);

}

And then imported just the letters I needed one by one, like this:

T = 11.83;

o = 13.77;

r = 11.73;

b = 10.09;

j = 6.73;

oe= 14.94;

module tbear(){

letter("font/T.dxf",0);

letter("font/o.dxf",T);

letter("font/r.dxf",T+o);

letter("font/b.dxf",T+o+r);

letter("font/j.dxf",T+o+r+b);

letter("font/oslash.dxf",T+o+r+b+j);

letter("font/r.dxf",T+o+r+b+j+oe);

letter("font/n.dxf",T+o+r+b+j+oe+r);

}

To find reasonable letter-widths (the T+o+...-part) I used what I found in the font.scad file created by the font2openscad script. Using the letters one by one gave me two advantages

- The opportunity to make the sign more beautiful by translating each letter manually. (Extremely time consuming of course.)

- Avoiding OpenScad messing up Scandinavian letters.

I am aware that OpenScad has added support for Unicode and that they are adding native support for extruding text (look here), so the method I'm describing in this blog post is mostly relevant for old OpenScad builds like my own.

The complete script for creating my little mailbox sign can be found here. A render of it looks like this:

Getting a Two Color Print With One Bowden-fed Print Head And Monochrome Filament

To get the sign out in two colors, I wanted to pause the print exactly when the last

rectangular layer was done, before starting on the letters. I wanted this pause, so

I could change filament manually because I use a rather long Bowden tube.

I knew I used 0.2 mm z-lift, 0.3 mm layer height and that the rectangular base

was exactly 1.5 mm thick, so to find the critical moment in the gcode was just a matter of

searching for G1 Z1.8000. I then inserted directly into the gcode

commands to

- Retract 1 cm filament (G1 F3420.000 E...)

- Make a 2 cm z-lift (G1 Z... F10200.00)

- Pause SD-print (M25)

- Set extruder coordinate to whatever it should be when the manual filament-switch is done and print is resumed (G92 E...).

Anyway, here's how the end result looked like:

It's surprising how fun a simple sign can be when I really should be studying ;)

- tobben

Combining STLs and removing internal faces with Meshlab

I needed to glue together some stls recently, that fit together like the pieces in a puzzle. Like this:

In short, I wanted to snap the right walls together and remove the resulting double internal faces. The screendump is from Netfabb Basic, but it won't let me "merge selected parts" because I don't have a "pro-licence". So I found a tip here here that I used with some modifications.

First, I imported all the meshes into Meshlab and flattened the visible layers. This gives me all the parts in a single mesh. I then gave all faces "quality numbers" based on how visible they were. This made it possible to select the internal faces only and delete them.

The sequence of Meshlab commands was

Filters -> Mesh Layer -> Flatten Visible Layers

Filters -> Color Creation and Processing -> Ambient Occlusion - Per Face

Filters -> Selection -> Select Faces by Face Quality.

With min=0 and max=0.05 I got this selection:

If you look closely, you see that some internal faces in my buildings are also selected. Those are also unwanted, so getting them selected is like an extra bonus =)

That did the trick for me. Hope it does for you to ;)

- tobben

Explanation of basic RepRap mechanics (Swedish)

I crawled the web after an image of me and a 3d-printer today, to use in an article about the Martineåsen Project in the local newspaper. Surprisingly I stubled upon an old video of myself, from another newspaper. You need a paid membership to see it, so i put it here.

- tobben

The Martineåsen Project

The start of it

I received a call recently, from the Geo-data department of the municipality. They were developing some new housing in Martineåsen, and wondered if I could print it for them, scale 1:2000. It turned out my dad had tipped them about my RepRapping. I printed them a test piece and dad talked me into promising them fifteen pieces of landscape prints, each of them maximizing the print area of Gomle (19 x 19 cm). I thought the project was total madness right from the beginning. This would be an order of magnitude bigger than my most complicated print thus far, and it was to be done with the most unstable printer I've ever built, having access to two old laptops as my only computing power.

Creating a 3D model from contour lines

I didn't have access to any licenced 3D software what so ever, so I tried various free alternatives and started to have some limited success with Google SketchUp. I won't go into details here, but it turned out that creating the surface was really trivial (although computationally intensive). Looking around in the menus I found Draw->Sandbox->From Contours which transformed my contour data into a surface. Perfect.

However, to create an stl, you need a watertight model, not just one surface, so I needed to build walls and floor myself. Easy peasy was my first thought. It took me five working days (well, most of the time I were just waiting for my dads poor laptop to finish processing/rendering). I won't go into detail here, but the solution involved Simplify contours plugin, Projections plugin, Selection toys and Intersecting surfaces. My recommendation is: don't ever try to process large map data files with SketchUp and an old laptop. It doesn't work well.

Everything crashes

I managed to get out two pieces, looking roughly the same as the demo print.

Then lightning struck and destroyed my FTDI-chip! Luckily, I had a new Melzi circuit board lying around. I carefully moved all wires from the old Melzi to the new Melzi, uploaded firmware to the new board and everything seemed jolly good again. Then I suddenly lost contact. I unplugged and replugged the USB, and guess what? My laptop processor was suddenly toast! My new circuit board transformed my beloved laptop into a sad piece of molten plastic! Some of the following debugging is described here. The mistake was my own. I had not attached the minus side of the 12 V power chord tight enough.

Everything just works

When the hiccups of my new board was ironed out, the following 13 pieces printed more or less smoothly. Each peace took ca 12 hours to print, so my dad took the time to learn how to make time-lapse videos while waiting. This is the next last piece printing:

We also made a time-lapse of the mounting process:

- tobben

A Hanging RepRap

I've dreamt of a RepRap that uses ceiling and walls its frame for some time now. It would use lines and spools instead of smooth rods, belts and linear bearings. This blog sort some of my thoughts around it.

The idea

The printer I dream of would be all in one hanging unit, interfacing with the outside world only through filament (direct extrusion), hot end, power chord and four lines. Microcontroller, stepper motors and extruder would all sit on the hanging unit, so the room in which it operates wouldn't need to add any other details than four anchor points.

Benefits

- No time spent building frame, except four anchor points.

- Large print volumes.

- Would require no desktop when idle, if it could retract itself up close to the ceiling.

- Cheap.

- Few parts.

Difficulties

- Make firmware compensate for the unusual geometry.

- Avoiding rotations.

- Making anchor points.

The unusual geometry isn't actually that tricky to compensate for. We have four lines, so every point in the print volume will have a corresponding tuple of four line lengths. Converting from Cartesian xyz-coordinates to these tuples of four line lengths is just a matter of using Pythagoras' theorem.

The issue of avoiding rotations is the one I fear the most. Maybe it is necessary to hang the printer in 3 lines from the ceiling, and use 2 parallel lines to each of the remaining anchor points, to make the printing unit stable enough. That configuration is the one used by brandonheller's SkyDelta. The SkyDelta is by the way proof that a hot end can be given stable movement, only by using lines.

Making anchor points is maybe the biggest no-selling argument for this type of printer that I can see. While anchor points saves the desktop space, and makes it possible for people in small apartments to have a dangling printer, I suspect that many don't want to/can't screw that many holes in walls and ceiling.

Please check out the development thread for comments on this :)

- tobben

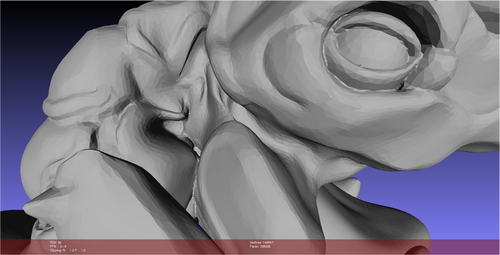

Second Attempt at Printing the Grue

Made a second attempt at printing the Grue figure from the (really cool) Teslagrad game. My last attempt was documented here.

This time around, I decided to go for splitting the figure in several planes parallel to the xy-plane and the yz-plane, and keep the auto-generated support material setting in Slic3r.

To do the splitting, I used Netfabb Basic's really nice splitting interface. I prefer simple, light and open software, so I tried splitting with OpenSCAD and Slic3r first, but the file were simply too messy and I didn't manage to repair it. I have to say Netfabb is pretty good at handling stls with intersections, holes, flipped normals and that kind of stuff. Anyways, here's how the model was split:

The print took ca 10 hours, glueing it together took ca 30 minutes and removing support material never actually finished. Unfortunately, much of the support material was impossible to remove, and some of the removed material took with it pieces of the actual figure.

There are two aesthetic issues with it that really bothers me. First, the clued contact surfaces did not fit each other perfectly. The clearly visible lines you see in the picture was as good as it could get. I suspect this mismatch to be due to a slack in the y-belt. The printer I used was the Mendel I built for my Mum and Dad last summer, and it hasn't really received the love it deserves. The second issue is all the dots of support structure that has tainted the figure like warts. PLA support structures for PLA figures really sucks. I hope this is the last time I try that.

I will probably try to print this again, since I can't stop bothering about those little issues...

- tobben

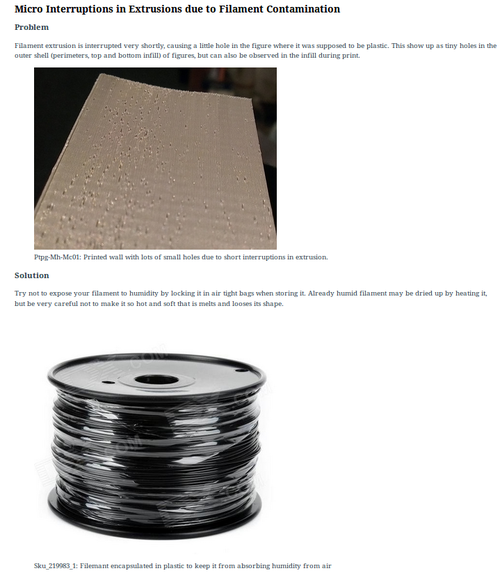

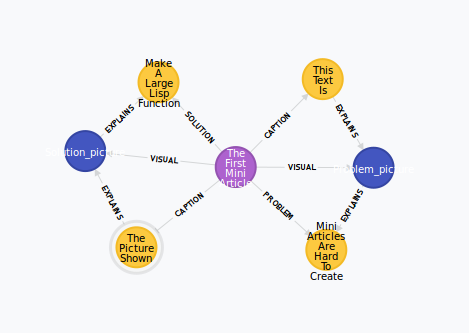

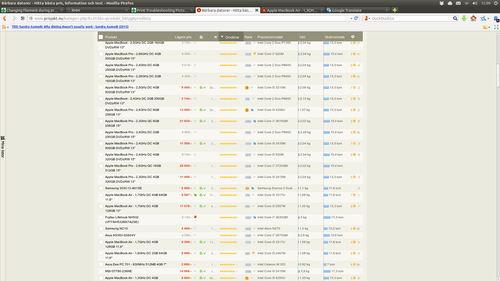

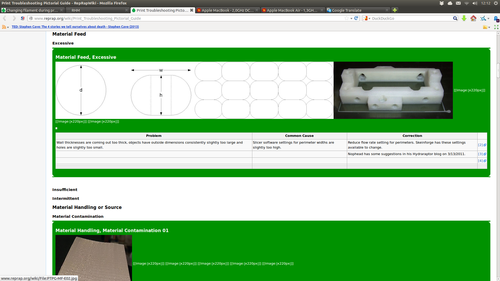

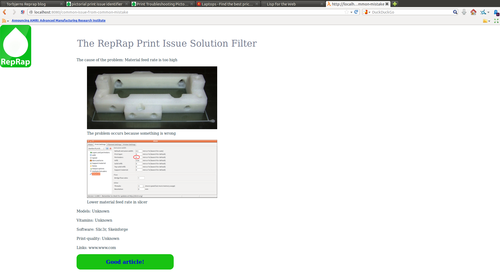

What Print Issue Solution Filter Is and What It Does

Hi there, Internet! The past week, I've gotten some feedback that people (even really technically talented ones) don't understand what the web app is and what it does, so I thought I might try to give an explanation.

I'm considering renaming it to something like Mini Article Structuring and Searching App or something, because there's nothing in the Lisp code that's specific to RepRap. The users decide what kind of knowledge is structured with it, but anyway let's use RepRap knowledge as our driving example.

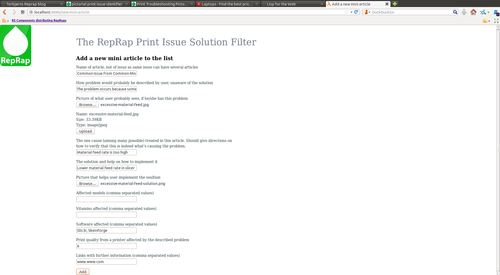

Defining the Mini Article

The first thing PISF does to structure knowledge, is defining a short but strict template, called a Mini Article, that has seven things:

- A title

- A written description of a problem

- A picture explaining the problem

- A caption to that picture

- A written description of a solution to the problem

- A picture describing the solution further

- A caption to that picture

By reading a lot of RepRap blogs, I have observed that many of us perform small pieces of pretty well structured research. Often the aim of our little experiments is optimizing a small detail of our 3d printing setup. My thought was that the Mini Article template could serve a similar role as report templates does in the academical world.

Sorting Mini Articles

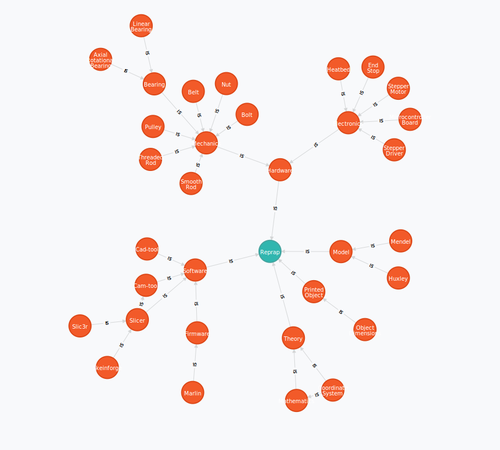

PISF stores these Mini Articles as seven nodes in a graph database. The layout looks like:

The paragraph nodes and the picture nodes may have relations that point into another set of nodes, called the "Category Bush". It looks like:

Searching Mini Articles

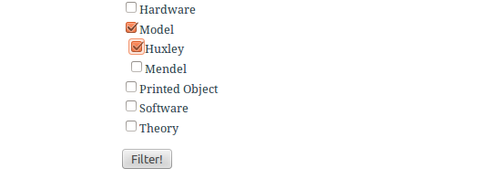

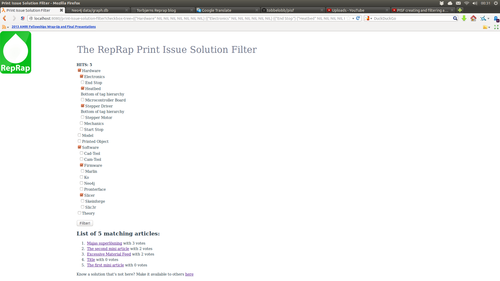

Arriving on the PISF homepage, the user is presented with a set of checkboxes. The names of these are loaded directly out of the Category Bush by starting in the Reprap node (the green one in the figure above) and traversing one step outwards via IS-relations. When the user checks a box and presses filter, checkbox-structure is rebuilt, with the node corresponding to the checked boxes treated like the Reprap node was before, in its own hierarchy of sub-checkboxes. It looks like this:

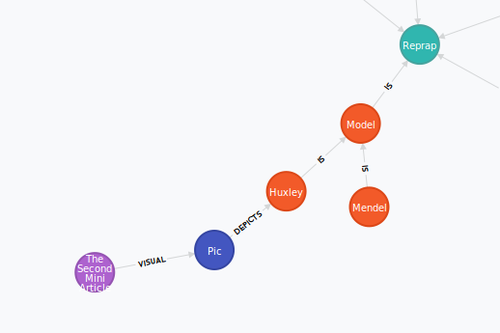

Back in the graph database, PISF will find the paths of the following pattern:

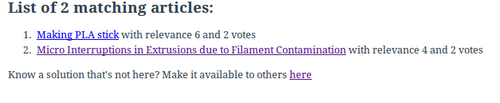

The user that just pressed filter will be presented with an updated list of Mini Articles. They are first sorted by relevance and then by number of votes. Relevance is found by counting the number of paths from the chosen categories to the respective Mini Article. That count is including the paths that go via sub-categories, but excluding the paths containing a loop in the category bush. It looks like this:

That's it for today. I'll come back to this pisf-thing when I've tried to actually use it ;)

- tobben

We're online! Sort of...

I just got my little web app, PISF, up and running on a server. Go check it out here! As you will see, it only has three articles as for now. Making it available to everyone was the last point on my prove-the-concept list. From here on I will seek input, inspiration, ideas from you guys. If people like it, maybe we can develop it further together.

Web programming with common lisp has mostly been pure amusement. The few daunting moments I've had has mostly been caused by bugs in Slimv (once it actually refused to compile my code because of a parenthesis inside a comment! I feel like a bad person for not bug reporting that properly. Sorry), and other external programs.

If you enjoy reading lisp source-code, here are a list of my favourite parts (see the github repo for the code):

- The macro

bind-cypher-returns-and-loopfound around line 50 inpisf-backend/pisf-backend.lisp. - The package-wise logging system defined in the three

logging.lispfiles. (Thanks to a git-repo I stumbled upon and stole this idea from. I honestly can't find it again.) - The macro

name-conventionizefound around line 30 inpisf-backend/pisf-backend.lisp - Discovering that a triangular pattern in a graph-database lets me

reuse nodes while avoiding confusion. Look at pictures in

pisf-backend/screenshotsto see how the mini articles are laid out in the graph database. The Cypher (database) queries needed to maintain this structure turned out to be monsters, but that's another story. - Discovering that I did not have to worry about loops in the tag/category hierarchy, because Neo4j will stop matching if it finds the same relationship twice in a single path during a single search.

- Discovering that I could sort based on relevance and based on votes, just by

adding

ORDER BY relevance DESC, votes DESCin line 187 inpisf.lisp. - Discovering that I could build a Cypher query in a loop quite easily.

This is used around line 510 in

pisf.lisp, merely as a way of getting around having to pass node-id's from one page to another, but amusing nonetheless. - A lot of Edi Weitz' work, that I've taken huge advantage of,

is beautiful.

cl-ppcre:do-matchesmade the job of writingescape-except-links(line 370 inpisf.lisp) so easy, I felt like I was cheating.

Getting Hunchentoot to actually serve outside my local network was a lot more tedious than I'd expected. In the end, I found a wonderful tutorial that led me to webfaction's hosting service. My experience with them so far has been as awesome as they promise in their ads. Through ssh'ing my hired server, I've been able to

- Compile Clisp from source with already installed

make - Compile SBCL from source with newly compiled Clisp

- Download and install Quicklisp

- Download Oracle JDK 8 and Neo4j and run them

- tobben

Presenting the Print Issue Solution Filter. Again

I've been working a this idea of a web app that filters small articles with RepRap know-how for a few weeks now. The idea is to let people find specialized information fast, without typing.

Take a look at this youtube clip. to see it in action. It also have got a github repo. Hope you like it. I'll write more about it later.

- tobben

Small soldering with cheap equipment

I recently had the choice between doing a kamikaze soldering or buying another new Melzi board, after one of the small people in the family happened to rip the USB connector loose. Of course I chose the kamikaze soldering. I thought it should be possible because the data transferring connectors had all broke in the soldered points, so only solder was left on the PCB and all the data transferring legs were intact. I only had to apply heat and pressure. The preparation was in three steps:

- Make the soldering irons tip completely flat with a file

- Look really closely at the points to be soldered

- Do it several times with a cold soldering iron to rehearse

I heated all the connectors simultaneously with the flat tip, for maybe one half second, and it was done. Three of the four non-transferring legs (the corners) had taken all the solder with them when they broke, so I used two component epoxy glue to attach them firmly to the PCB. The result looked like this

To save myself from having to do this too often, I now always zip tie my USB cables:

When building this same Mendel this summer, I had an even worse soldering problem. Merlin mystically reported the z-home switch to always be open. Investigations with a multimeter and with the help of the datasheet showed that the problem was a bad solder on one of the processors legs! Luckily, this was one of the corner legs, so it was one of the most accessible ones. My friend sluggo taught me to file the soldering iron to a sharp point, like this

To avoid having to bend the processor leg, I wetted the tip with a minimal amount of solder that I scraped onto the processor leg, not waiting for the solder on the PCB to actually melt. This was the result

It worked perfectly ever after. In general my open hardware stuff break more often than my other electronic hardware, but when it does it's more often possible to repair because datasheets, code, explanations etcetera are available. Occasionally I even learn something, and that has value too =)

- tobben

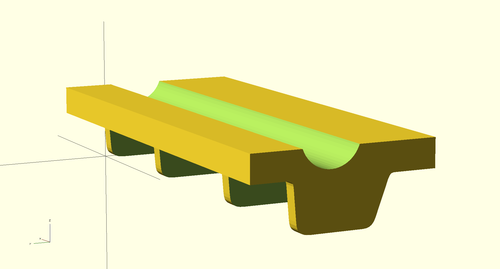

Making a Ring with a Rope

My girlfriend and I are getting married this summer, and we thought it would be nice to have the ring custom made, so I made a little sketch of our idea in OpenSCAD. The sea is important to us, so we wanted to symbolize that with a rope that runs in a track in the middle of an otherwise plain wedding ring.

The plain ring with the track was really easy to get into OpenSCAD, because

of the rotate_extrude function.

rotate_extrude. Thanks to jokern for suggestions

on how to model this.

Cadding the rope was a bit trickier, because rotate_extrude

doesn't take any twist-parameter or anything like that. This turned out to be

a frustrating limitation, so I decided to try out

OpenJSCAD instead. To my delight, I found

that it had a method called solidFromSlices that seemed to

suit my needs.

solidFromSlices.

Unfortunately, solidFromSlices doesn't automatically detect that

it has created a loop (OpenJSCAD maybe has other functions for that, I didn't

get the complete overview), so the generated stl gets its "start-wall"

(start of the rotation) and "end wall" intersecting inside.

These self-intersecting surfaces made OpenSCAD refuse to import

the rope-ring from OpenJSCAD. Oh no! :-O Fortunately, the intersecting

surfaces had one special attribute that made them easily removable: They

were all lying flat in the xy-plane. I made an ASCII-version of the stl,

opened it with Gvim, and found several surfaces with normals exactly along

the z-axis

facet normal 0 0 1 and some of them deviated from that with

a number of order -16. The last line in the picture shows how to search for

these facets with Gvim.

With all the intersecting facets removed, importing worked like a charm again.

The files I used for this project (included the OpenJSCAD code) can he found here. Hope you guys enjoyed.

- tobben

Making PLA prints stick reliably

I recently tried out a trick I learned from NumberSix's 3D printing blog and Richrap's blog about applying a layer of diluted PVA a based glue to the kapton tape heat bed, to make PLA stick better. One part glue and nine parts water was the first I tried, and it did the trick perfectly for me. After having had problems with getting my glossy orange PLA to stick at all, big prints like this is now reliable like a walk in the forest

As well as keeping large prints from not warping, it lets even the tiniest dots in a first layer stay in place. I tried two different glues that both worked fine. Here is one of them:

This method may make your prints stick too hard to your printbed. Start with small amounts. Also, first layer adhesion depends on a lot of things, and is being eagerly discussed on the reprap forums, so not everything will work for everyone, but this is my go to solution for now =)

- tobben

A Very Short Introduction to Basic RepRap Workflow

This is for you who somehow have gotten you a ready-to-use RepRap, but don't have any previous experience with either RepRap, 3d-printing or CAD software. We're going to print a calibration cube, and I'm just going to assume that everything goes smooth. Billions of things that can go wrong, but I will avoid mentioning too much about them. The programs chosen are just the ones I use. They're not good, nor bad. They just are what they are.

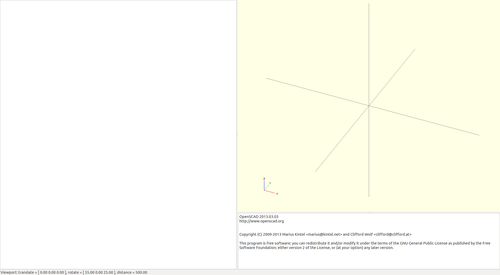

Start with downloading and installing OpenSCAD. When installed and executed, it should present to you a window like this:

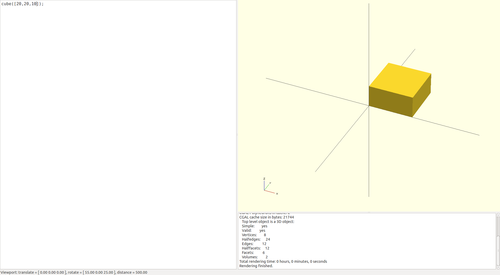

We want our calibration cube to be 20 mm wide, 20 mm deep and 10 mm high, so we

enter cube([20,20,10]); into the text editor in OpenSCAD, and

compile and render it. The "Compile and Render" is done either by pressing F6,

or by finding Design > Compile and Render (CGAL) in the menus.

Your OpenSCAD should now look like this:

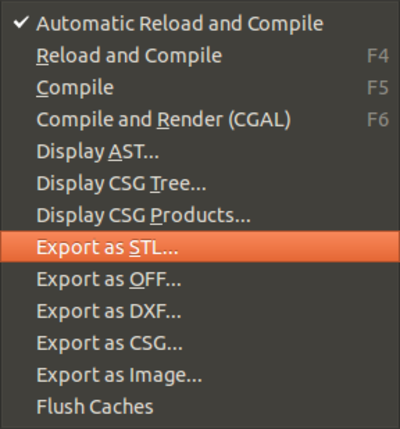

We now want to export our model to a format that the next program in our tool chain can use. We choose the most widely used format, which is called .stl. You export it from OpenSCAD by finding Design > Export as STL... in the menus:

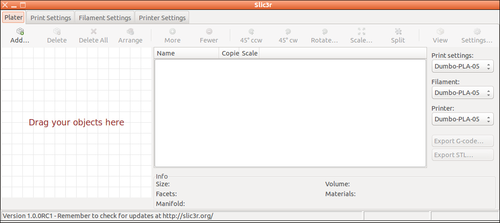

The modelling is now finished, and we start to prepare the model for the printer. Download and install Slic3r. When installed and executed, it should present to you a window like this:

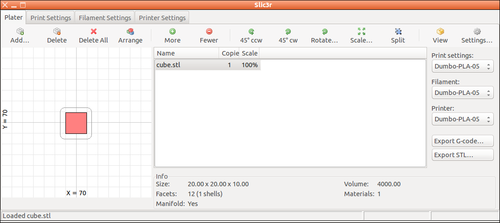

To import the calibration cube, press Add... button. When the cube is imported, it looks like this:

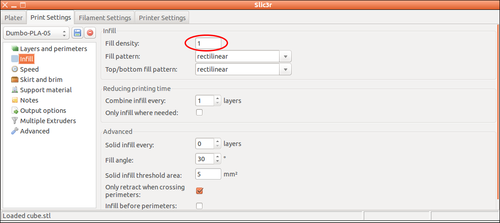

Slic3r is a program with many options. We're just going to look at ca five of them. First, we want to assure that the cube is printed as a solid cube. Click the tab called Print Settings and in the menu on the left click Infill. We want to set the Fill density to 1:

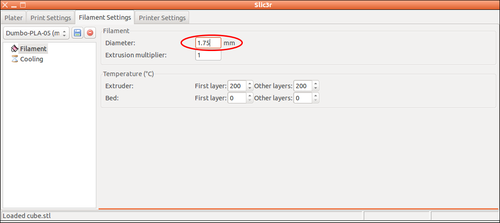

Click "Save" (the little blue icon) and note the name of your Printer Settings config (To the left of the blue icon). The next option we're going to change is in the Filament Settings tab. The default value for Diameter is 3. Measure the diameter of your filament with a caliper, and put the measured value into the Diameter field.

Again, click "Save" and note the name of your Filament Settings config. Note that the default extruder temperature of 200 degrees Celsius works well if your filament is made out of PLA. If you're not sure what kind of filament you have, check it up first.

Also, if you don't have a heatbed, put the bed temperature of 0 degrees Celsius, like shown in the figure. If you have a heatbed, and will be printing with PLA, anywhere between 40 and 60 degrees Celsius is a good starting point for experimentation.

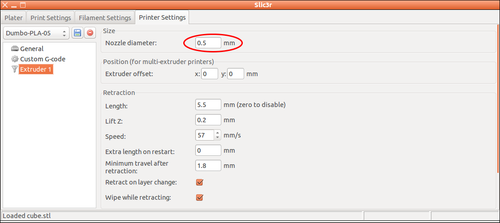

Next, we're going to look at Printer Settings. Measure the bed size of your printer. Feed the measured values it into the Bed Size fields, and put the values divided by 2 into the Print Center fields.

The last value to check/update is in Printer Settings, Extruder 1, Nozzle Diameter. If you don't know your nozzle diameter, check it up and feed in the correct value.

Save your printer settings and return to the Plater tab. Assure that the names of the Print Settings config, Filament config and Printer Config are the same ones as the ones you saved to earlier. Next, press the Export G-code... button and save the .gcode file somewhere you will find it later on. You have now created the actual data that will be sent to your RepRap! The next step is learning how to send it.

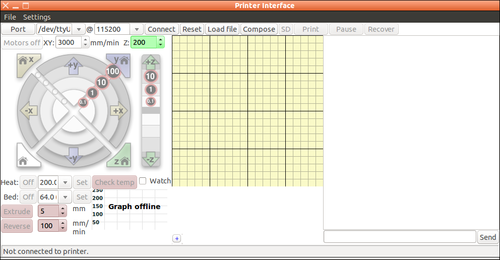

Download and install Printrun/Pronterface. If you're on Windows, maybe this link can be of help. When installed and executed, it should present to you a window similar to this:

Click the connect button. Hopefully the printer will respond with "Printer is now online." or something similar. On Windows machines, it will probably not. At least on W7 and older, you will need to install drivers to communicate with the printer.

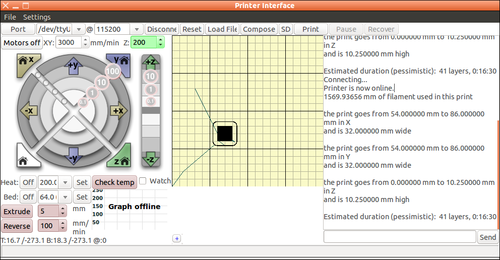

When the printer is connected, we want to load our gcode. Press Load file and select your file. Pronterface should now look something like this:

If you've come all the way here, you're now ready to press print. Your printer should respond by starting to heat up its hot end and start to print the first layer within a few minutes. The print will probably have an awful lot of problems, depending on how "ready-to-use" your printer really was.

I would estimate a less than 1 % chance that the info in this post makes a total newbie able to print him/her-self a cube. You will probably need some more specialized info to get all the details right, but I hope this post has enabled you to ask the right questions and/or trump your way through some of the loops without noticing the potential pitfalls.

PS! The manual for OpenSCAD is found here.

- tobben

Printing litophanes

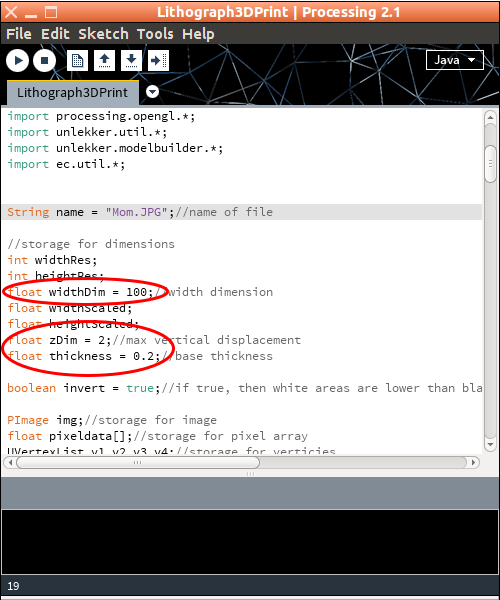

I read Peter Blacker's excellent blog post about making lithophanes with RepRap recently, and was inspired to print a couple for my parents. I first found a nice picture of my Mom, and scaled it down to 300x200 pixels to make it easier to handle. I then used processing, the Model builder library created by Marius Watz and a sketch created by Amanda Ghassaei. Her instructable contains details about installing the library and using the script.

I put the file Mom.JPG in the same folder as the sketch and opened the sketch in

Processing. I followed Peter Blacker's advice and set zDim to 2, so I got

20 steps from white to black when printing at 0.1 mm layer height.

I also gave the tip about cropping pictures and putting thickness to 0

a go. The result was, as expected a very slim background, showing up as

"snow" in Meshlab, like on an old TV without a signal

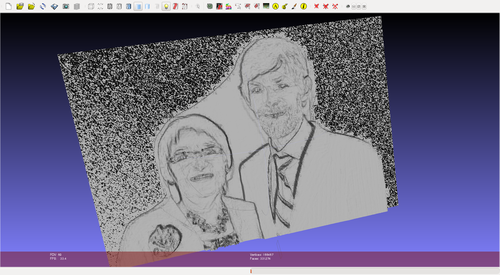

The results looked like this

Notice that the left litophane looks slightly more detailed than the right one? The right one was actually made with more pixels per mm (500 pixels wide), and had the same number of layers from white to black (20 x 0.1 mm). I think the reason for the difference in detail if that when I sliced the right one I was using "wipe on retraction", whereas when slicing the left one, I did not. Z-lift was used on both.

Before slicing litophanes of pictures with some more important parts (like human faces), it can increase slicing speed to use the reduce faces tip on the unimportant parts. Mark the unimportant vertices before making the reduction.

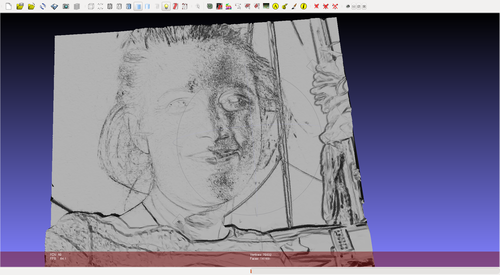

This one came out pretty nice, but shows signs of drooling

Too bad that this process was so technically demanding. It would like to teach my parents how to do it on their Reprap. Anyone has ideas about making it more seamlessly? Installing Processing and having to install libraries is a bit over their heads I think, but getting out too complicated stls causing Slic3r to hang is probably what will make them give up.

- tobben

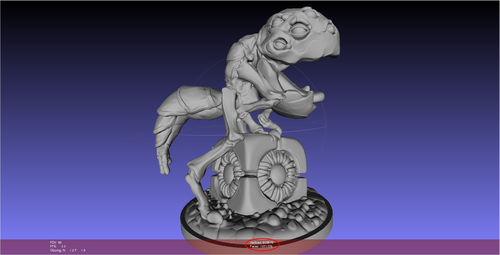

Printing a complicated figure with PLA

My brother and his indie game company recently released the awesomely awesome game Teslagrad. To celebrate, I wanted to print him a monster from the game. An artist at the company, Aslak, sent me this impressive monster, called a Grue, in a CAD model:

Even though I had a pretty snappy computer to work with, and the latest (1.0.0RC2) version of Slic3r, slicing hung time and time again. To make the slice possible at all, I did four things:

- Reduced the number of faces

- Used the resolution option

- Set "number of threads" to 1

- Set support material pattern to "rectilinear grid" instead of default "honeycomb"

Thanks to the Slic3r blog for the first three these tips! Reducing the number of faces was mainly a matter of finding the option Filters > Remeshing, simplification and construction > Quadratic Edge Collapse Detection in Meshlab. More details about this is available here, but I found the number of faces to be the only important option. I simplified down to 300k faces without any noticeable artifacts, except when zooming in really close:

To clean it up, I ran it through a Netfabb repair (locally of course, don't want to give away Aslak's work to the cloud service). The resolution option was set to the length travelled my one microstep on my x- and y-motors on my printer, and number of threads was set to 1, as mentioned earlier. The figure still wasn't sliceable on my machine though.

The big breakthrough, and also the big mistake I did then was to change the support material pattern. Slicing went smooth as a baby's bottom, and I started to print, but I had forgot to change the pattern spacing! It was left at the default 2.5 mm spacing, which is ok for a honeycomb pattern, but far too little for a rectilinear grid. The result was a nearly impermeable clump of PLA. After about three hours of fighting away support material, this is was what came out:

The conclusions after making this print were

- Use greater pattern spacing than 2.5 mm, when printing rectilinear grid support material.

- Don't ever use lots of PLA as support material for a PLA print.

- tobben

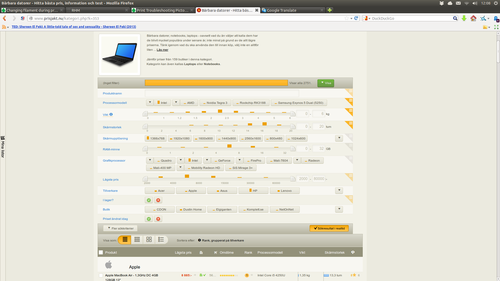

Introducing the Print Issue Solution Filter web app

I got an idea the other day, when I was reading a forum thread. The RepRap community definitely needs a more effective way to troubleshoot, than asking random strangers on forums. There should exist a quick troubleshooting tool for common RepRap problems on the internet. After a short discussion with sluggo, we agreed that web apps that apply filtering of a database, with live updating, is a very effective user interface. In particular, we love the interface of shopping sites like price spy

What I mean should be sorted and filtered is a list of mini-articles, like the green rectangles on this wiki page. The wiki-page contains great information that the community should strive to make even more accessible.

I asked in the forum thread if someone knew how to implement a minimalist version of such a web app, but didn't get any response, so I decided I had to set out to learn it myself. I really love working with the three structure of Lips-code, so I decided to take Adam Tornhill's great book Lisp for the Web as a starting point. This is where I am today, will be working further tomorrow:

The code is currently 500 lines of messy lisp, but I plan putting it in a shareable state as soon as possible.

- tobben

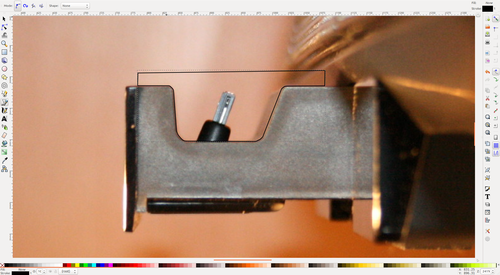

Making custom architrave profiles

My Mum got a stereo with a docking station that didn't fit her tablet for Christmas. She still wanted somewhere to put the tablet close to the stereo, so my brother and I made this profile

It was made by first taking a photo from the side of the ipod dock, and loading it into Inkscape. Using the "draw straight lines"-tool (Shift+F6), a profile similar to this (I didn't save the original) was drawn:

The background picture was deleted after this, and a OpenSCAD dxf

(thanks again to the plugin) was exported.

The dxf was then linear_extruded, and four cubes and one cylinder was cut out of it to

produce the following shape

The source code can be found here.

- tobben

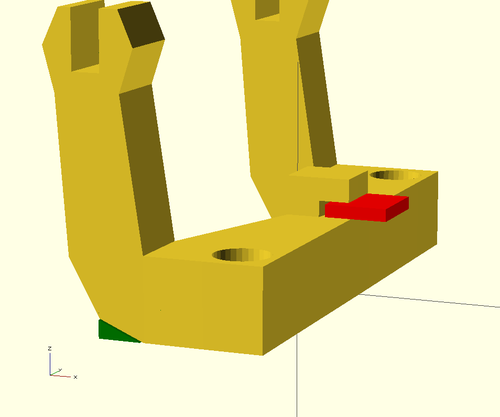

CAD'ing support structures when PLA printing

I recently had to print out some small overhangs with PLA. After a previous PLA support material experiment, I decided to try to model the support structures myself (I was inspired by one of nophead wonderful blog Peel-able support?. In OpenSCAD, it looked like this:

I found that ca 0.15 mm vertical gap gave the best results with my current plastic and slic3r settings. This will of course vary wildly depending on plastic type, geometry, layer height, extrusion width and so on. I found the results satisfying:

I will definitely CAD my own support material again, when only PLA is available as print material.

- tobben

Minor Reprappro Mendel tweaks

I was recently preparing some large prints with my parent's Reprappro Mendel, and decided to do a bunch of minor tweaks. First, I went to Reprappro's own documentation to search for inspiration, and they had prepared this =D. I decided to to both the "Fan mount":

and the "Alternative positions for extruders":

I haven't found any elegant way to tension the y-belt on this design easily. At least I found a way that doesn't consume a lot of time or concentration, the belt tensioner by Reuben on Thingiverse. This is how it looked

- tobben

Sourcing a Reprappro Mendel in Larvik. The rest

To actually make the finishing touch to make the Mendel operative was much more difficult than expected. Troubles with electronics took most of the extra time. The Melzi I had found cheap on ebay had the wrong sort of connectors (not screw connectors), and an Atmega 644p instead of an Atmega 1284p. The standard Melzi stepper drivers, A4988, also requires active cooling for currents greater than 1 A.

For reasons I still don't understand, we could only control the motors to turn if we sat velocities really low. Maybe Marlin and Pronterface disagreed on whether to use absolute or relative coordinates, causing the movements sent from pronterface to be interpreted as impossibly fast (due to voltage rise times etc) by Marlin? In the end, one of the A4988's and the heat bed transistor burned because of too high motor current a frayed untinned HB connection respectively). I decided to buy a completely new Melzi from a new source (reprap.me), to tin all connectors and to only use motor currents less than 1 A.

The new Melzi board had two problems though:

- Z-homing didn't work

- Extruder motor just stuttered

The z-homing problem looked like

this (youtube video).

Issuing M119 (Get Endstop Status) showed that Marlin thought the z-switch was

always open. It was solved with a kamikaze soldering directly on the Atmega's one

leg. It is described in an

earlier post and in this

forum thread.

The extruder motor was luckily a problem i software. The solution is described

in this

forum thread.

These troubles ceirtanly slowed the project down, and only one day was left

of my summer holydays to teach my parents how to use the machine. The first

print was a handle to a dipstick. It printed

nicely like this (youtube video). And

we soon went on to print a Julia vase (desperate attempt to convince Mum this

machine is of any value:

After a couple of weeks into the semester, Dad mentioned on the phone wanted to try it out to print a smartphone case. I went on Thingiverse and found the Monogrammed iPhone case made by TheNewHobbyist. I modified it, sliced it, emailed the gcode and got this picture from Dad a couple of days later:

Success! I'm very excited to see how my parents relationship to the Reprap develops. Thanks for listening.

- tobben

Sourcing a Reprappro Mendel in Larvik. Weekend 1 and 2

At this point, my summer job in Oslo had started, so I could only work during weekends. Pace naturally slowed down. This gave the postal service time to catch up. I received endstop switches, glass bed, 623-bearings, hot-end, XLR-plug, stepper motors, the Melzi board and filament. Unfortunately, the filament I received had the wrong diameter, so the order must be placed again... Ordering is hard and depends on a lot of unknown factors.

Since I used a M6 rod for the z-axis, and the motor shaft had 5 mm shafts, I couldn't use a uniform tube as linkage. The solution I found was to drill out a couple of glue gun patrons. I described them in an earlier post.

- tobben

Sourcing a Reprappro Mendel in Larvik. Day 6 and 7

Not much could be done day 6. Managed to make an insulating sheet with a handsaw and a drill from the dxf on Reprappro's Mendel repo on Github:

At day 7 dad came home from work with an old aluminum traffic sign! I cut it out to a heat spreader (except the corner holes).

Drawing the outline from the dxf supplied by Reprappro and cutting it with a grinder was fairly straight forward.

I was lucky to do this project in a house with lots of hardware stuff lying around. For example, I could stretch out a old unused springs I found, and use them to hold up the insulator + heat spreader:

- tobben

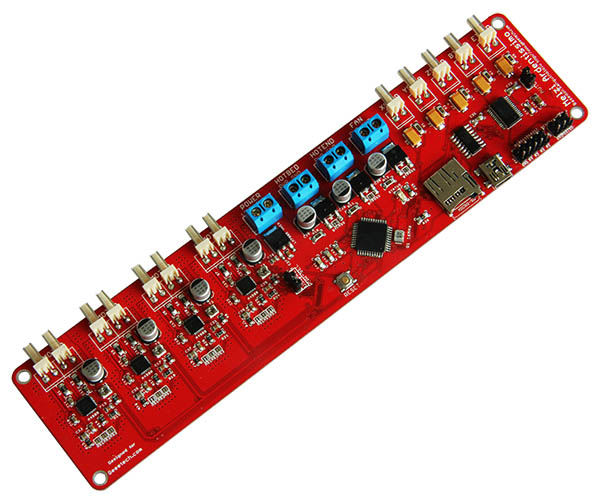

VRR firmware and a different way of communicating with 3d-printers

I've started working on a, as far as I know, new type of firmware. The main idea behind it is to minimize the need of processing power on the actual printer by reducing it to a slave that only relays low-level commands from the computer. Of course it will have to take care of some timing and buffering but that's about it. Since this type of protocol is not compatible with the current G-Code based one I'm also working on a driver that will emulate some generic G-Code receiving printer to make it work as a drop-in replacement.

The upsides I see with the master-slave vs client-printer model are many, first of all unless you plan on equipping you printer with a >100$ cpu your computer will always be better at doing pretty much all the calculations needed for a print - thats why we do the slicing on it! Another key reason why I found the idea worth exploring is the much improved debugging capabilities, many G-Codes instructs the printer to perform several actions (e.g. G28 - home all) if any of these fail no further information than that the complete instruction failed is given. Now, using a printer that exports information about what pins it has and what they do and then simply receives ctrl-msgs pertaining those pins, i.e. a semi-transparent hardware abstraction protocol (kinda directly controlling the pins on the board using ctrl-msgs) or StAHP, each action can be performed with minute control giving the user the ability to pinpoint exactly when and where the printer fails. Having this type of control over the printer also means pausing, aborting, adding or subtracting parts (to/from) a running print-job will be much easier.

A basic printer-computer handshake would look something like this (M - master/computer, S - slave/printer)

format: seqno, sender: <msg> 00, S: <init printer> // handshake init 00, M: <printer confirm> 01, S: <printer id> 01, M: <printer id confirm> // M checks if it has Ss ctrls cached, if not: 02, S: <N controls installed> // # controls on printer (N) 02, M: <ctrls confirmed> 03, S: <ctrl 1: type> // type of ctrl 1 (stepper motor, fan ctrl, etc) 03, M: <ctrl 1 type confirm> 04, S: <ctrl 1: func> // function of ctrl 1 (e.g. type = motor, func could be x/y/z-axis) 04, M: <ctrl 1 func confirm> // further info about func exchanged 05, S: <ctrl 1: M pins> // # pins for ctrl 1 (M) 05, M: <ctrl 1 pins confirm> 06, S: <ctrl 1, pin 0: func> // function of pin 0 on ctrl 1 06, M: <ctrl 1, pin 0, func confirm> 07, S: <ctrl 1, pin 0: min> // min value of pin 0 07, M: <ctrl 1, pin 0 min confirm> 08, S: <ctrl 1, pin 0: max> // max value0 08, M: <ctrl 1, pin 0, max confirm> ... // this continues for all pins on all ctrls R0, S: <ctrl N, pin K-1: max> // where K is the number of pins on ctrl N R0, M: <ctrl N, pin K-1, max confirm> R1, S: <max bufsz: L> // # ctrl-msgs that fit in the printers buffer R1, M: <bufsz confirm> R2, S: <awaiting action> R2, M: <awaiting action confirm> ... // M can now start controlling the printerAs seen the handshake time can be reduced quite much if the master has a cache of the printers ctrls. As such a cache (config) file could be easily produced when writing/porting the firmware to different boards hopefully the start-up time of printers using this type of firmware can be reduced to almost zero.

This project is still in its infancy and the driver will probably not be ported to windows until the first stable version.

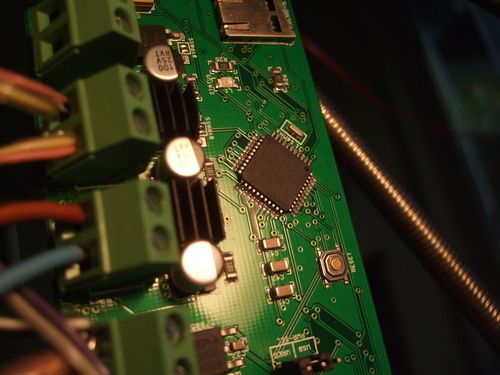

I'm using a left over Melzi Ardentissimo v.1 board from geeetech.com

to develop it so that type of board will probably be the first one to have a usable beta.

// sluggo

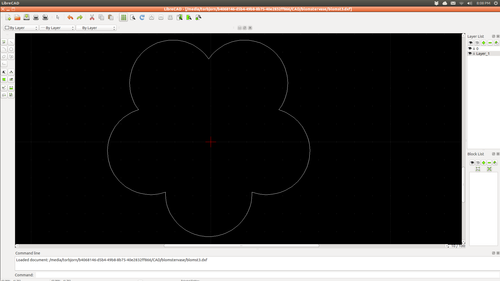

Making simple twisted vases

I recently printed some twisted vases. They were drawn by using an svg flower icon, LibreCAD, Inkscape (with polymaker's plugin) and LibreCAD.

I first opened the svg in Inkscape and saved it as "OpenSCAD DXF Output" (thanks to the plugin). I then removed unwanted edges, scaled it and centered it in LibreCAD.

In OpenSCAD, the line of code to extrude the vase was

linear_extrude(height = 123,

convexity = 6,

twist=130,

slices=30)

import("blomst3.dxf",layer="Layer_1");

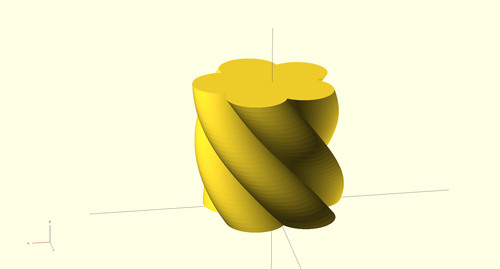

giving the following model

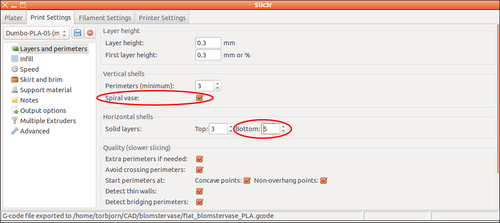

I then exported as stl and imported it into Slic3r. To slice it a spiral vase, you need to tick a box and choose number of bottom layers. The only other relevant setting is extrusion width.

I used an extrusion width of 0.83 mm for this large vase, to make it sturdy. Use lots of plastic (a fairly large extrusion multiplier or a similar setting) if you want the bottom to be water tight. Here is the result

The files I used are available here.

I also experimented with rendering and slicing it on my 7 year old laptop.

To make the laptop handle it, I had to remove 75 % of the line segments in the dxf. I did this by opening

it in Gvim, and removing every second coordinate-pair with a little macro, twice.

The coordinates are preceded by a line saying AcDbPolyline. Every x-coordinate is preceded

with a line saying 10, and every y-coordinate is preceded by a line saying 20.

To be able to do the CGAL compile and render in OpenSCAD, I also reduced the number of linear-extrude-slices.

I also found I had to use a SD-card directly in the Melzi to get fast enough

data transmission of the gcode.

The result is

the leftmost and biggest (I also scaled it up a bit) vase on this picture

When printing the rightmost one, my glue gun patron z-coupling solution failed.

It turned out that the friction between the tube and the motor shaft was too low. The fix was just to change the upper zip tie with a hose clamp.

The leftmost vase on the picture above has a little excessive edge on the bottom. This is due to a failed attempt to make it water tight, by welding a new bottom layer to it. To make this weld successful, I think you need to press it against surface hotter than the one I used, for a very short time (~ 1 sec). Aluminum foil in a hot frying pan might do the trick, I will try that next time. Here's how it looks from below

- tobben

Sourcing a Reprappro Mendel in Larvik. Day 5

For the z-axis, I had chosen M6 instead of M5, because I had a pair of M6 lying around. Making them, and their nuts fit into the printed x-motor-bracket and x-idler-bracket was a PITA, involving lots of difficult sanding. Even getting the M3 nuts down into the nut traps was really difficult and time consuming because of the small holes and overall low quality of my printed parts.

Eventually, I had x-brackets with nuts fit super-tight which is nice.

Finally, I got 623 bearings (1.7 NOK each!) from Ebay, and Igus clip bearings and a hobbed bolt for the Mini extruder from eMakershop. I'm quite surprised that Igus clip bearings are used. They are pretty hard to find, even on the internet, and they seem easy to replace with a home made alternative. I would definitely replace them with printed nylon bushings in my own design.

- tobben

Sourcing a Reprappro Mendel in Larvik. Day 4

Today was a better shopping day. A local hardware store cut me the smooth rods I needed for 25 NOK. "And that gives us huge margins", was the owners comment on the price, so I guess smooth rods are really cheap when you buy in large quantities. If I had a garage, I would try to do that.

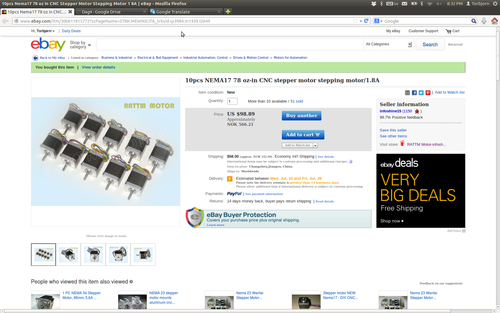

Since Larvik couldn't deliver all the small stuff I needed, I turned to good old Ebay for belts, linear bearings, M2.5 screws, XLR-contacts and stepper motors:

Sluggo helped by making a little wiki to store all the important specs (in Swedish).

- tobben

Sourcing a Reprappro Mendel in Larvik. Day 2 and 3

Bought a bunch of screws and searched the whole town for seven 623-bearings. I only found three of them, and they were excessively expensive (nearly 100 NOK each!). Screws of size M2.5 weren't available either. Nobody in the hardware and electronics shops knew what an XLR-socket was, so I ended up buying on of a wrong type. Linear bearings of the type LM8UU were also impossible to find. One shop could order really expensive ones if I gave them the exact measures, but I declined. Couldn't find smooth 8 mm rods either. Conclusion: The parts needed to build a Reprappro Mendel are not readily available nor cheap in the city of Larvik.

Four of the printed parts split in half because of a weak layer (had some problems with the extruder when I was printing them). They were easily glued together with two-component epoxy though. Enough hardship for today. One thing actually went really well. I managed to involve Dad when mounting together the skeleton:

I think involving him in the build greatly increases the chances of him wanting to test it when it's operational.

I also had a failed attempt to buy a Prusa Nozzle, which I would really like to try out. They were sold out. It's nice to see business going well for Reprap open hardware producers. There's lots of interesting hot ends out there, but to save time and effort I decided to go for a standard Reprappro hot end kit from Emakershop this time.

- tobben

Sourcing a Reprappro Mendel in Larvik. Day 1

Last summer holidays, I decided I wanted to build a Reprap to my parents to see how useful it could be to them as non-computer-wizards with little experience of the idea of 3d-printing. To make it a little more interesting, I decided to use printed parts from my Printrbot+, sigrid, and to buy the vitamins one at a time, preferably in Larvik. It would be a nice test of how available these Reprap parts really are (or of how good Larvik is as a hardware shopping city...). For BOM and all other information, I used the build-instructions from reprappro.com. I got to work immediately and ordered a heatbed:

I also ordered a borosilicate (heat resistant glass) plate:

All the M8 threaded rods + nuts were bought in the local hardware store Biltema for 913 NOK. We could have saved 360 NOK by choosing galvanized steel instead of stainless, but dad thinks stainless looks better. Cutting the right lengths were done with dads grinder.

- tobben

Hello, World!

Welcome, RepRappers! I've spent a lot of time RepRapping over the past year, so I thought it was time to make a blog about it. I'm planning to post at least once a week for at least 10 weeks forward. The posts will mostly be condensed everyday tinkering, but I have a hope that over time, I can use my knowledge from engineering physics studies to make some actually useful contributions to the RepRap community.

Added 1-2-2014:

Great news! My friend sluggo will also be posting here from time to time.

I would say it radically improves

the chances of posts with actually useful contributions to the community appearing on this blog.

Welcome, sluggo!

Enjoy!

- tobben

Links

Hangprinter Campaign: Bountysource Salt

Hangprinter Merchandise USA: Spreadshirt.com

Hangprinter Merchandise Sweden: Spreadshirt.se

Hangprinter Project: [1], [2], [3], [4], [5], [6], [7], [8], [9], [10], [11], [12], [13], [14], [15], [16], [17], [18], [19], [20], [21], [22], [23], [24], [25], [26], [27], [28], [29], [30], [31], [32], [33], [34], [35], [36], [37], [38], [39], [40], [41], [42], [43], [44], [45], [46], [47], [48], [49], [50], [51], [52], [53], [54], [55], [56], [57], [58], [59], [60], [61], [62], [63], [64]

Hangprinter Project Homepage: hangprinter.org

Print Issue Solution Filter Project: [1], [2], [3], [4]

Sourcing RepRappro Mendel in Larvik: [1], [2], [3], [4], [5], [6], [7]

Archive: 2014, 2015, 2016, 2017, 2018, 2020

Github Profile: link

Gitlab Profile: link

Hangprinter project on Gitlab: link

Vimeo User: link

Youtube User: link

Twitter User: link

Master's Thesis: link

Linkedin Profile: link

Appropedia User: link

RepRap Forums User: link

Forums threads: Hangprinter version 1, Hangprinter version 2, Hangprinter version 3, List of Hangprinter threads

Source for this blog: Gitlab repo

Everything on this homepage, except the videos, is licenced under the Gnu Free Documentation Licence. The videos published via Vimeo or Youtube are also licenced via Vimeo or Youtube.